In the electronic equipment manufacturing industry, with the improvement of equipment performance, heat dissipation issues have indeed become increasingly prominent. High-performance electronic equipment usually runs at high frequency and high load, generating a large amount of heat. If this heat cannot be dissipated in a timely and effective manner, it will cause the temperature of the equipment to rise, which will affect the stability and reliability of the equipment, and may even cause equipment damage.

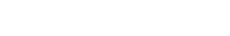

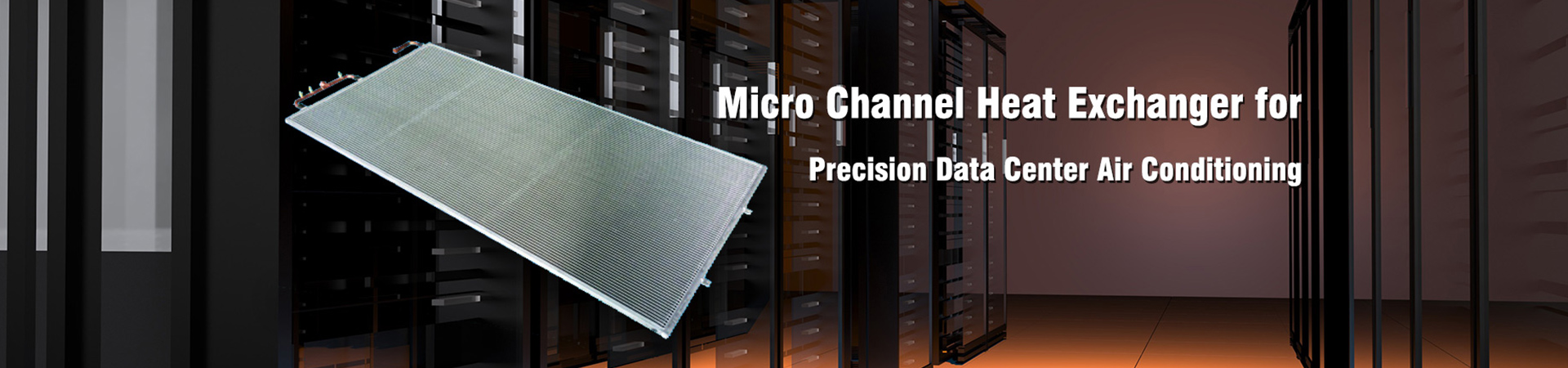

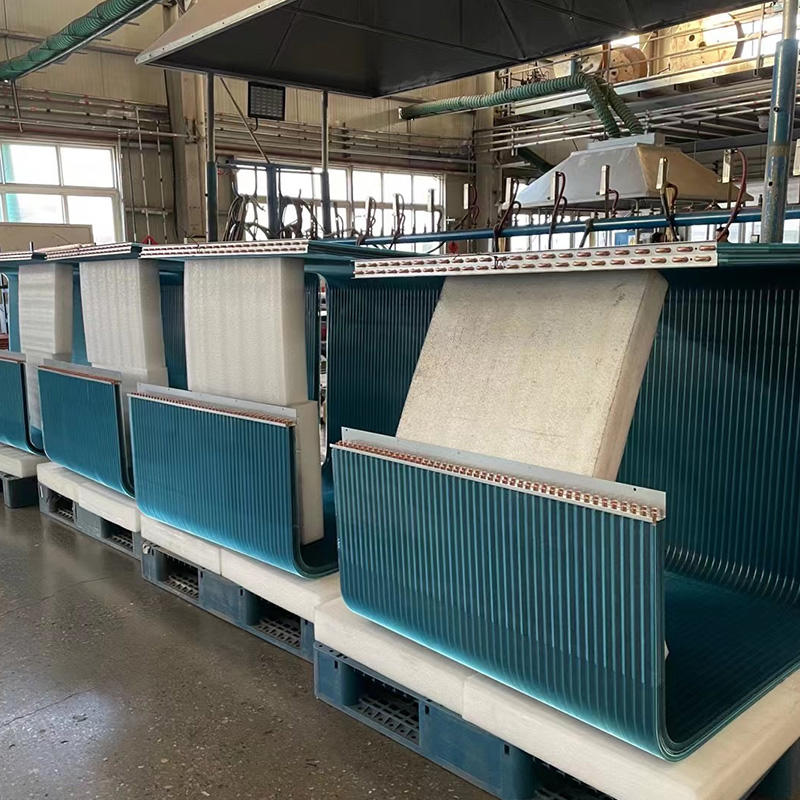

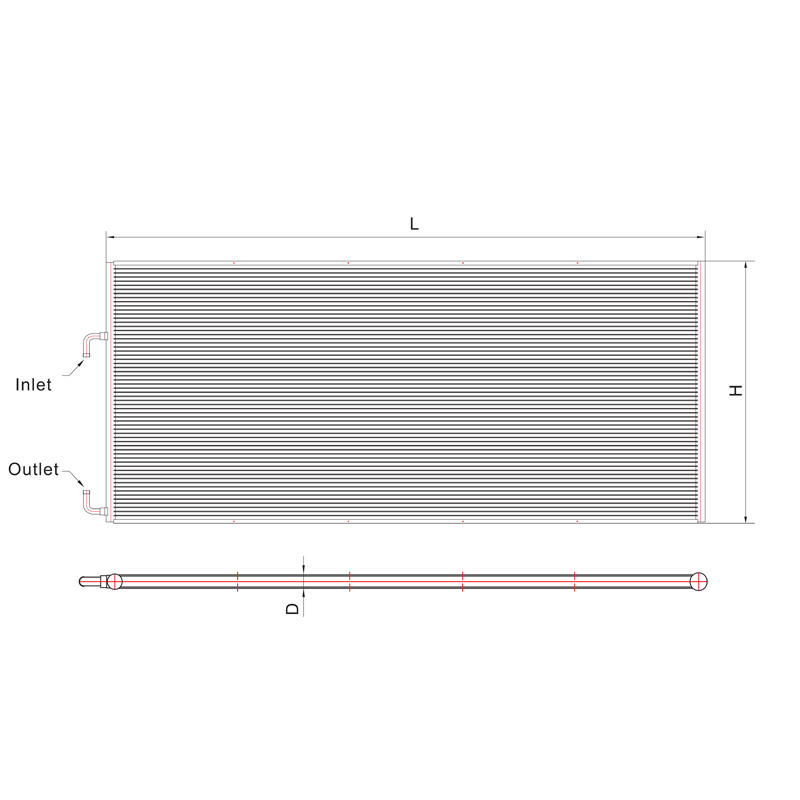

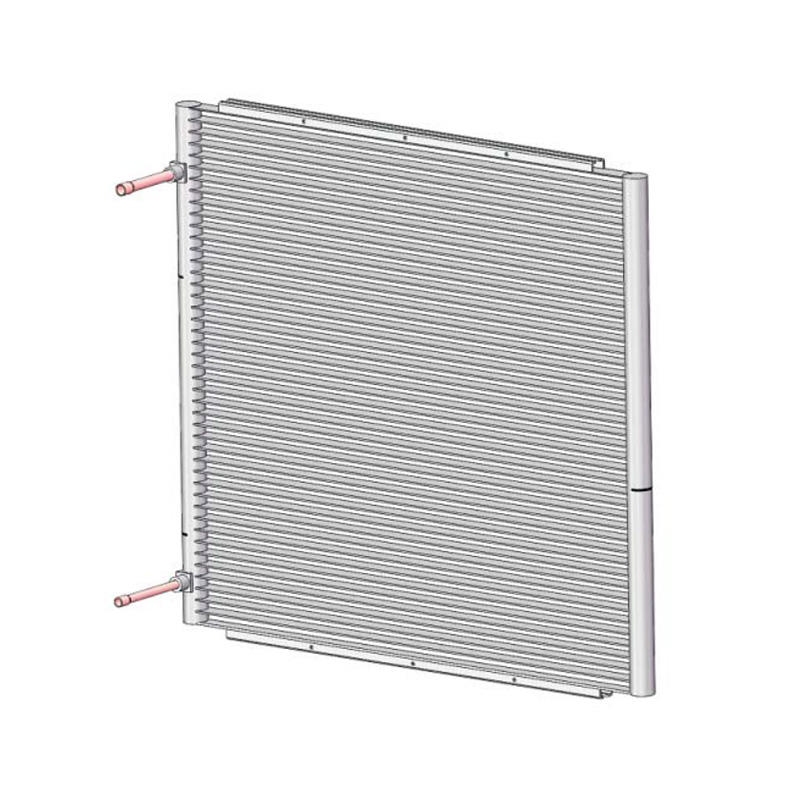

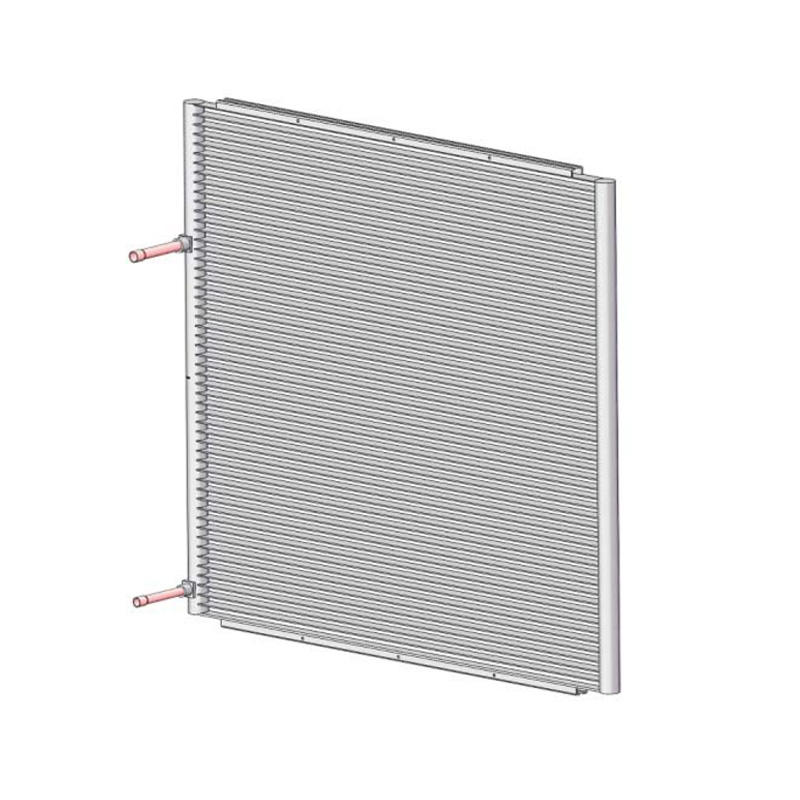

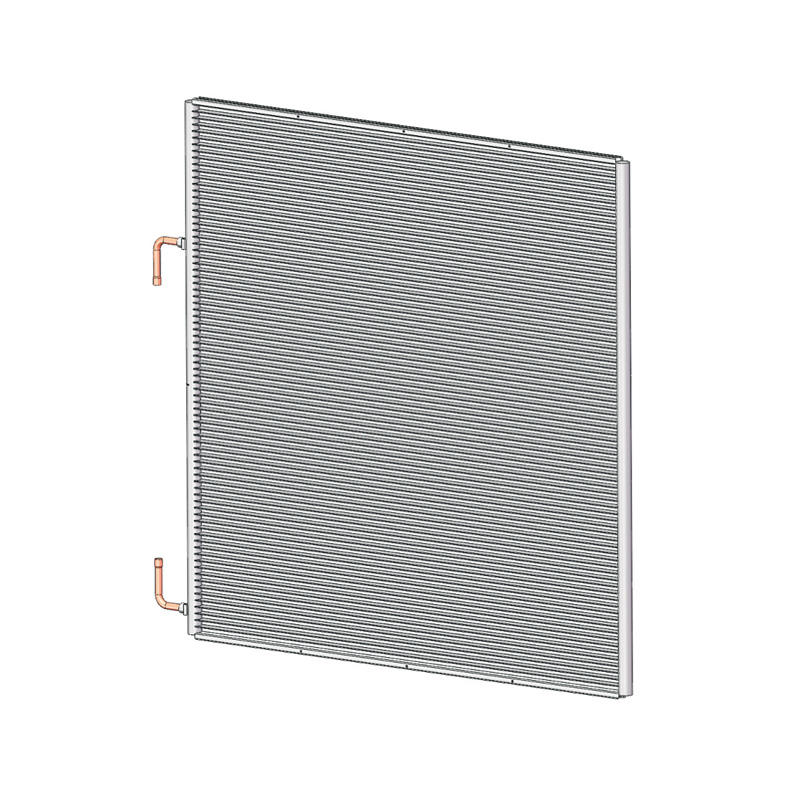

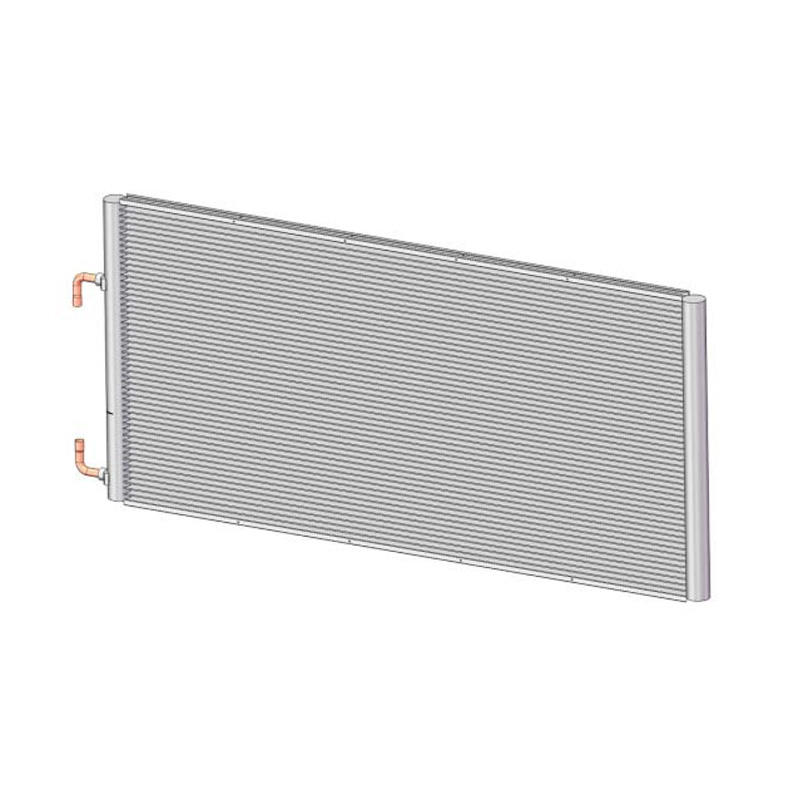

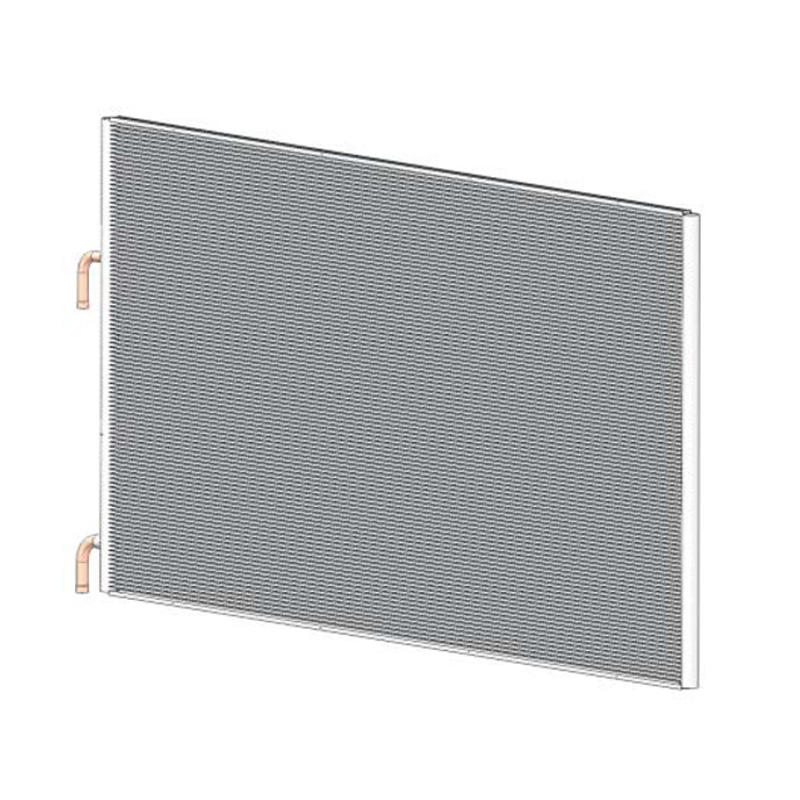

Aluminum Tube Aluminum Fin Heat Exchanger (aluminum tube aluminum fin heat exchanger) is a common heat dissipation device, and its thermal conductivity can meet the heat dissipation needs of high-performance electronic equipment to a certain extent. Aluminum is a metal material with good thermal conductivity. The design of the aluminum tube and aluminum fin heat exchanger increases the heat dissipation area and improves the heat dissipation efficiency through the design of the fin structure.

However, for particularly high-performance electronic devices, the thermal requirements can be very stringent. In this case, relying solely on the thermal conductivity performance of the aluminum tube and aluminum fin heat exchanger may not be able to fully meet the demand. In order to ensure the stable operation of the equipment, more advanced and efficient cooling solutions may be required.

These solutions may include using materials with higher thermal conductivity, optimizing the structural design of the heat sink, adopting active cooling technologies (such as fans, liquid cooling, etc.), and implementing intelligent temperature control strategies. In addition, for high-performance electronic equipment, heat dissipation design also needs to comprehensively consider factors such as power consumption, size, and cost of the equipment to achieve the best heat dissipation effect.

Therefore, although the thermal conductivity of aluminum tube and aluminum fin heat exchangers can generally meet the cooling needs of electronic equipment, for particularly high-performance equipment, other heat dissipation technologies and measures may need to be combined to ensure the stable operation of the equipment. . In actual applications, appropriate heat dissipation solutions should be selected based on the specific needs and conditions of the equipment.

Aluminum Tube Finned Tube Microchannel Condenser Heat Exchanger MCHE

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>