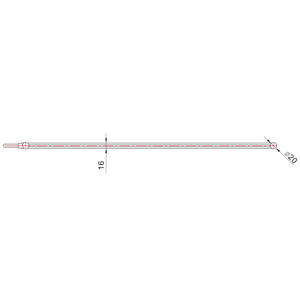

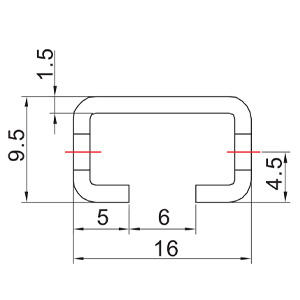

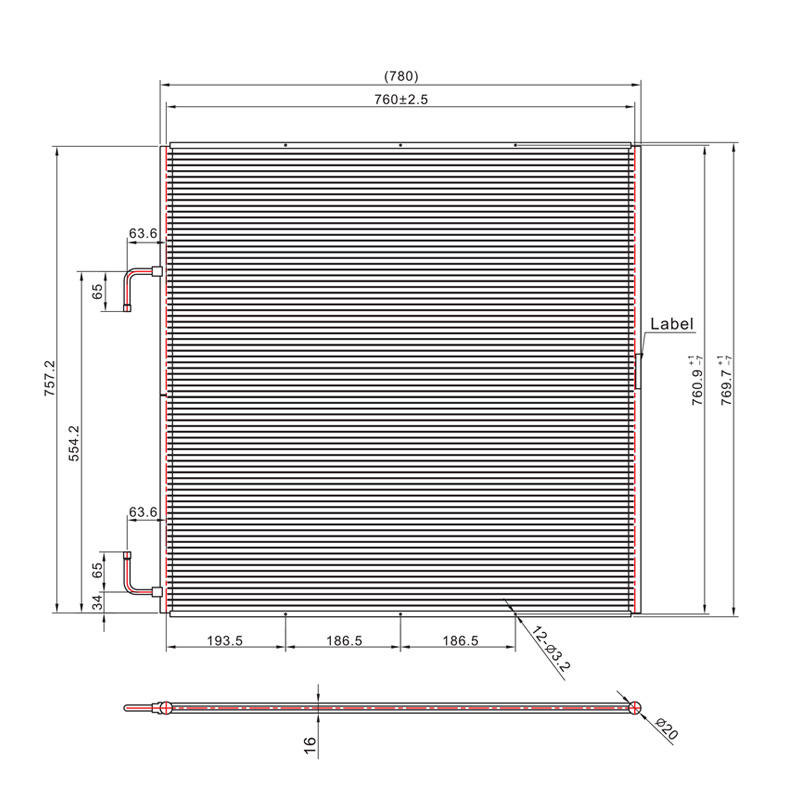

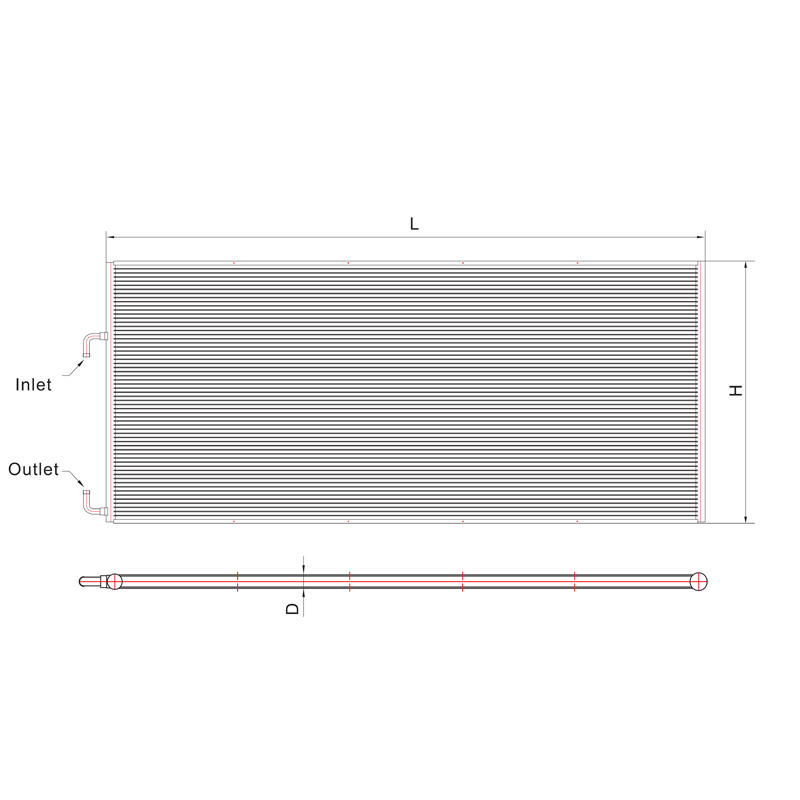

| Model | Coil length | Coil height | Coil depth | Fin pitch | Fin height | Manifold diameter |

| SC-1400 | 780[mm] | 769.7[mm] | 16[mm] | 1.1[mm] | 8.1[mm] | 20[mm] |

| 30.7[in] | 30.3[in] | 0.63[in] | 23[FPI] | 0.32[in] | 0.79[in] |

| Model | Tubes height | Number of tubes | Pass | lnternal volume | Inlet lD diameter | Outlet lD diameter |

| SC-1400 | 1.3[mm] | 79 | 42/37 | ≈0.95[L] | 9.52[mm] | 9.52[mm] |

| 0.05[in] | ≈58.09[in³] | 3/8[in] | 3/8[in] |

Mounting Bars

Aluminum MCHEs expand and contract when exposed to big temperature changes. Installation supports/bracketsmust allow the MCHE to move in two dimensions.

Performance Data

| Air Velocity | Performance [KW/Btu/hx1000] | ||||||||

| [m/s] | [ft/min] | R410A | R134a | ||||||

| △=10K △=18°F |

△=15K △=27°F |

△=20K △=36°F |

△=25K △=45°F |

△=10K △=18°F |

△=15K △=27°F |

△=20K △=36°F |

△=25K △=45°F |

||

| 1 | 197 | 5.8/19.8 | 8.8/30.0 | 11.7/39.9 | 14.8/50.5 | 5.6/19.1 | 8.4/28.7 | 11.2/38.2 | 14.0/47.8 |

| 1.5 | 295 | 8.0/27.3 | 12.2/41.6 | 16.6/56.7 | 20.8/71.0 | 7.6/25.9 | 11.6/39.6 | 15.4/52.6 | 19.2/65.5 |

| 2 | 394 | 9.9/33.8 | 15.2/51.9 | 20.9/71.3 | 26.1/89.1 | 9.4/32.1 | 14.3/48.8 | 19.1/65.2 | 24.3/82.9 |

| 2.5 | 492 | 11.7/39.9 | 18.4/62.8 | 24.7/84.3 | 31.0/105.8 | 10.8/36.9 | 16.6/56.7 | 22.3/76.1 | 28.4/96.9 |

| 3 | 591 | 13.2/45.1 | 21.0/71.7 | 28.3/96.6 | 35.3/120.5 | 12.2/41.6 | 18.7/63.8 | 25.9/88.4 | 32.1/109.6 |

| Air Velocity | Performance [KW/Btu/hx1000] | ||||||||

| [m/s] | [ft/min] | R404A | R407C | ||||||

| △=10K △=18°F |

△=15K △=27°F |

△=20K △=36°F |

△=25K △=45°F |

△=10K △=18°F |

△=15K △=27°F |

△=20K △=36°F |

△=25K △=45°F |

||

| 1 | 197 | 5.8/19.8 | 8.7/29.7 | 11.8/40.3 | 15.0/51.3 | 3.8/13.0 | 7.0/23.9 | 10.1/34.5 | 13.0/44.4 |

| 1.5 | 295 | 7.9/27.0 | 11.9/40.6 | 16.5/56.3 | 21.0/71.8 | 5.2/17.7 | 9.8/33.4 | 13.9/47.4 | 18.1/62.8 |

| 2 | 394 | 9.7/33.1 | 15.5/52.9 | 20.6/70.3 | 25.7/87.7 | 6.3/21.5 | 12.0/41.0 | 17.3/59.0 | 23.0/78.5 |

| 2.5 | 492 | 11.3/38.6 | 18.2/62.1 | 23.9/81.4 | 30.4/103.8 | 7.3/24.9 | 14.1/48.1 | 20.9/71.3 | 27.1/92.5 |

| 3 | 591 | 12.6/43.0 | 20.7/70.6 | 27.7/94.5 | 35.2/120.1 | 8.2/28.0 | 15.9/54.3 | 23.7/80.9 | 30.8/105.1 |

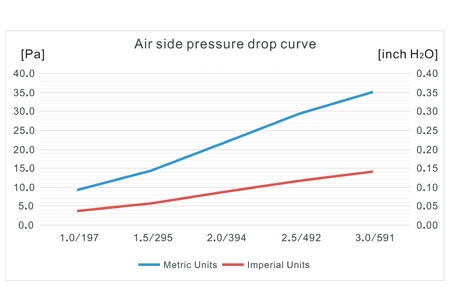

Air-side Pressure Drop Data

| Air Velocity | Pressure drop | Flow rate | |||

| [m/s] | [ft/min] | [Pa] |

[inch H2O] | [m3/h] |

[cfm] |

| 1 | 197 | 9.31 |

0.04 | 2107.90 |

1239.9 |

| 1.5 | 295 | 14.66 |

0.06 | 3161.94 |

1860.0 |

| 2 | 394 | 22.32 |

0.09 | 4215.93 |

2480.0 |

| 2.5 | 492 | 29.79 |

0.12 | 5269.91 |

3099.9 |

| 3 | 591 | 35.73 |

0.14 | 6323.89 |

3719.9 |

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>