Are there any upkeep necessities for a micro-channel heat exchanger with a condenser coil?

1. Cleaning: One of the most essential protection responsibilities is the everyday cleaning of the condenser coil. Over time, dirt, dirt, debris, and other contaminants can accumulate at the coil, decreasing its warmness transfer efficiency. Cleaning the coil enables to put off those deposits and improve airflow, making sure effective warmth dissipation. The frequency of cleansing may depend on elements just like the environment, utilization situations, and the presence of capability contaminants.

2. Inspecting for Damage: It is crucial to periodically inspect the condenser coil for any symptoms of damage which includes bent fins, leaks, or corrosion. Bent or damaged fins can limit airflow and decrease warmness switch efficiency. Any signs of leaks or corrosion should be addressed immediately to save you in addition damage and make sure proper functioning of the warmth exchanger.

3. Clearing Obstructions: Besides the condenser coil itself, it is necessary to test for any obstructions within the heat exchanger system. This includes examining and clearing any blocked air vents, ensuring there aren't any items obstructing the airflow around the condenser coil, and making sure right space around the heat exchanger for adequate air flow. These obstructions can negatively effect the heat transfer technique and decrease the overall efficiency of the system.

4. Checking refrigerant levels: The refrigerant ranges within the micro-channel heat exchanger want to be checked frequently. Low refrigerant degrees can have an effect on the warmth transfer method and positioned additional pressure at the compressor. If there are any significant changes inside the refrigerant stages, it is really helpful to touch a professional technician for further inspection and capacity recharging or maintenance.

5. Lubricating moving parts: If the micro-channel heat exchanger has any transferring elements, consisting of fanatics, it's miles critical to lubricate them as in step with producer hints. Proper lubrication facilitates ensure smooth operation, reduces friction, and prolongs the lifespan of the components.

6. Regular professional servicing: While ordinary cleansing and inspections can be finished by the gadget proprietor, it's miles advocated to schedule periodic expert servicing for the micro-channel heat exchanger. Qualified technicians can thoroughly investigate the device, pick out any potential troubles, carry out vital upkeep or replacements, and conduct specialised cleaning procedures to keep ultimate overall performance.

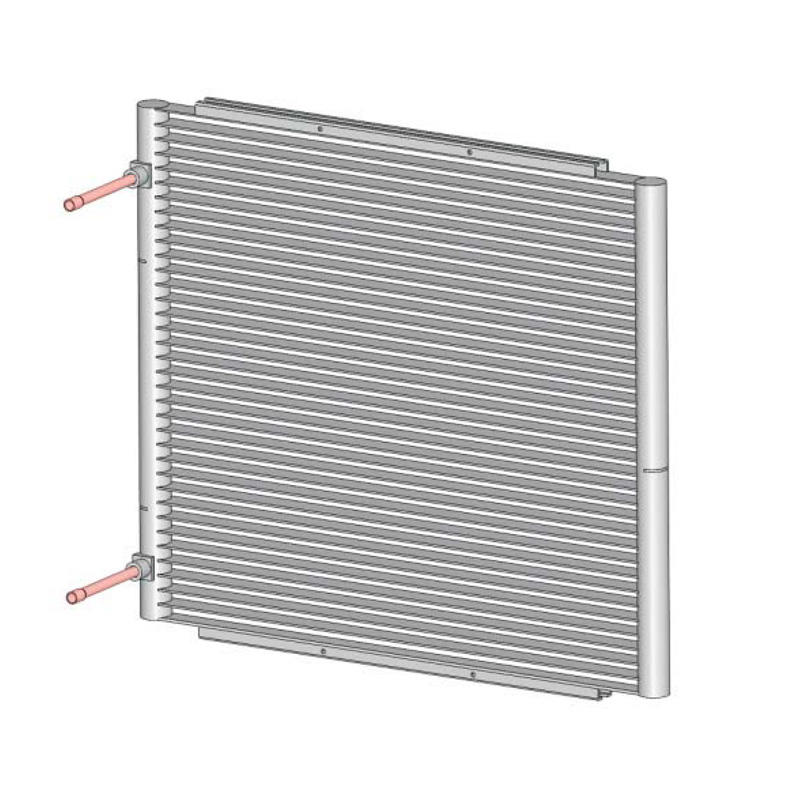

Can a micro-channel heat exchanger with a condenser coil be used in corrosive environments?

A micro-channel heat exchanger with a condenser coil may be used in corrosive environments, however positive issues ought to be taken under consideration. Corrosive environments have the capability to damage the heat exchanger and reduce its performance. However, with proper choice of substances and preventive measures, a micro-channel heat exchanger may be designed to face up to corrosive conditions.

The first thing to do not forget is the choice of corrosion-resistant substances for building the heat exchanger. Different metals and alloys have various ranges of resistance towards corrosion. For corrosive environments, materials consisting of stainless-steel or titanium are often favored because of their high resistance to chemical attack.

In addition to fabric selection, shielding coating or remedy methods can be used to further beautify the resistance of the heat exchanger to corrosion. For instance, making use of an epoxy coating, electroplating, or passivating the surface can save you direct contact between the corrosive surroundings and the heat exchanger structure, mitigating the threat of corrosion.

It is also critical to frequently look into and maintain the heat exchanger in corrosive environments. This consists of tracking the condition the coils, checking for any signs and symptoms of corrosion or harm, and directly addressing any issues located. Regular cleaning is likewise vital to put off any corrosive sellers or deposits that could have accumulated on the heat exchanger surfaces.

Furthermore, enforcing right air flow and air filtration systems can assist lessen the exposure of the heat exchanger to corrosive factors. This can save you the accumulation of contaminants or corrosive particles inside the surrounding air, thereby reducing the ability for corrosion.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>