What are the blessings of the use of micro-channel heat exchangers with SC-1500 condenser coils?

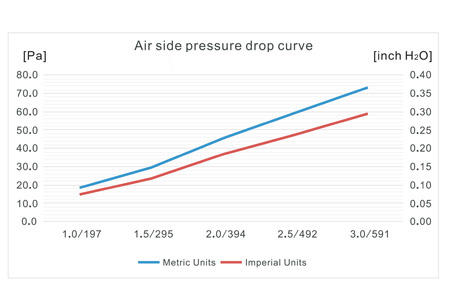

1. Enhanced Heat Transfer Efficiency: The micro-channel design of heat exchangers allows for a larger surface area compared to conventional heat exchangers. This extended surface location enables stepped forward heat switch efficiency by using maximizing the contact among the refrigerant and the coil. When teamed up with the SC-1500 condenser coil, that is mainly designed for such applications, the heat transfer is optimized even further. This partnership results in greater efficient cooling or heating tactics, lowering electricity intake and improving standard system performance.

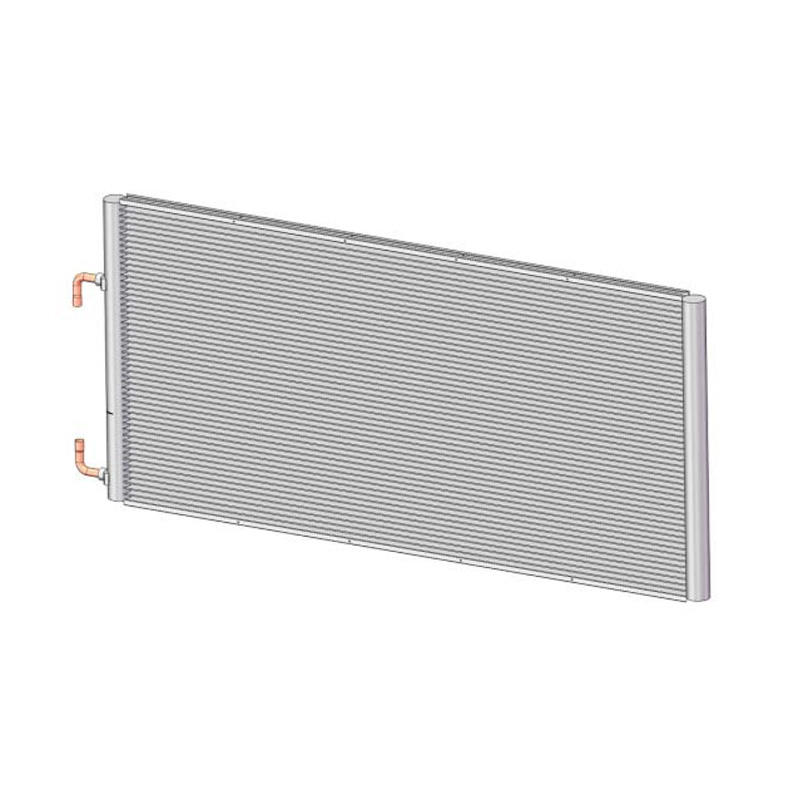

2. Compact Design: Another tremendous gain of micro-channel heat exchangers is their compact size. Their small footprint allows for simpler set up in confined space or congested environments. Combined with the SC-1500 condenser coil, which additionally possesses a compact design, this combination is extraordinarily beneficial in applications in which space constraints are a challenge, consisting of in automobiles, plane, or portable refrigeration units.

3. Reduced Refrigerant Charge: Micro-channel heat exchangers require a decrease refrigerant charge as compared to standard heat exchangers. This discount reduces the environmental effect in addition to operational prices. The SC-1500 condenser coil similarly optimizes this advantage by using presenting tremendous warmth transfer traits, bearing in mind a greater green use of the refrigerant rate. Lower refrigerant fee also complements machine protection and decreases the chance of refrigerant leaks.

4. Improved Performance at Low Refrigerant Flow Rates: Micro-channel heat exchangers, in combination with the SC-1500 condenser coil, show wonderful performance even at low refrigerant float costs. This belongings is mainly fine in programs where strength performance is essential, including in aircon systems or refrigeration units, because it enables to decrease energy intake with out compromising operational performance.

5. Corrosion Resistance and Durability: The SC-1500 condenser coil is typically constructed using substances that offer outstanding corrosion resistance. This durability is fundamental in making sure the durability and lengthy provider existence of the heat exchanger. Combined with the micro-channel design, which reduces the probability of fouling or clogging, the SC-1500 condenser coil ensures a low preservation requirement. This advantage now not only reduces downtime and renovation costs however additionally gives a greater dependable overall performance over an prolonged period.

How does the design of the SC-1500 condenser coil contribute to its effectiveness in heat exchange?

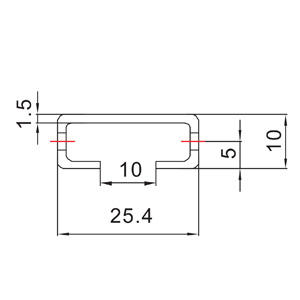

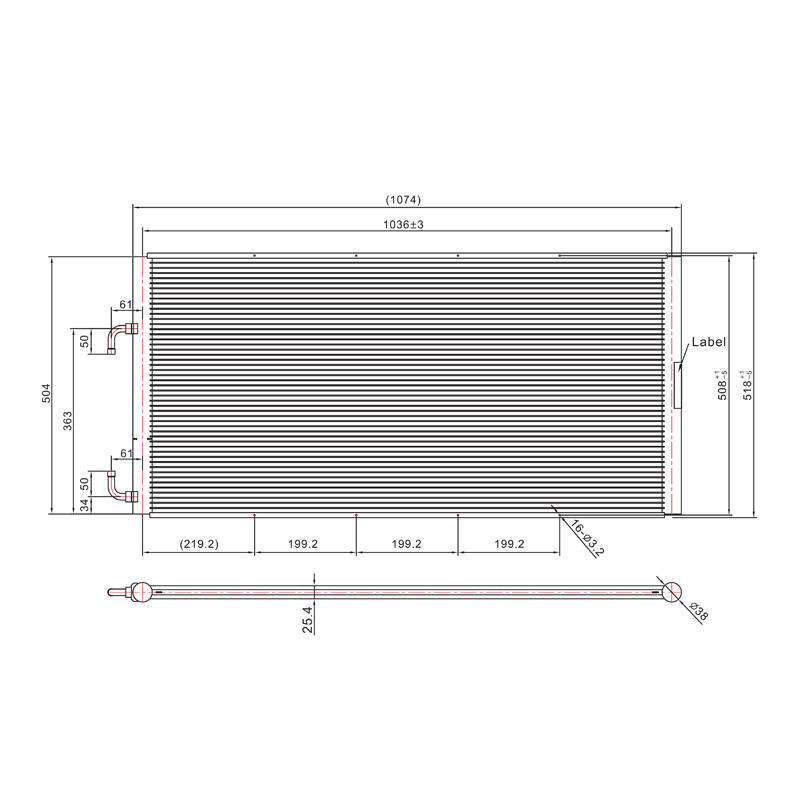

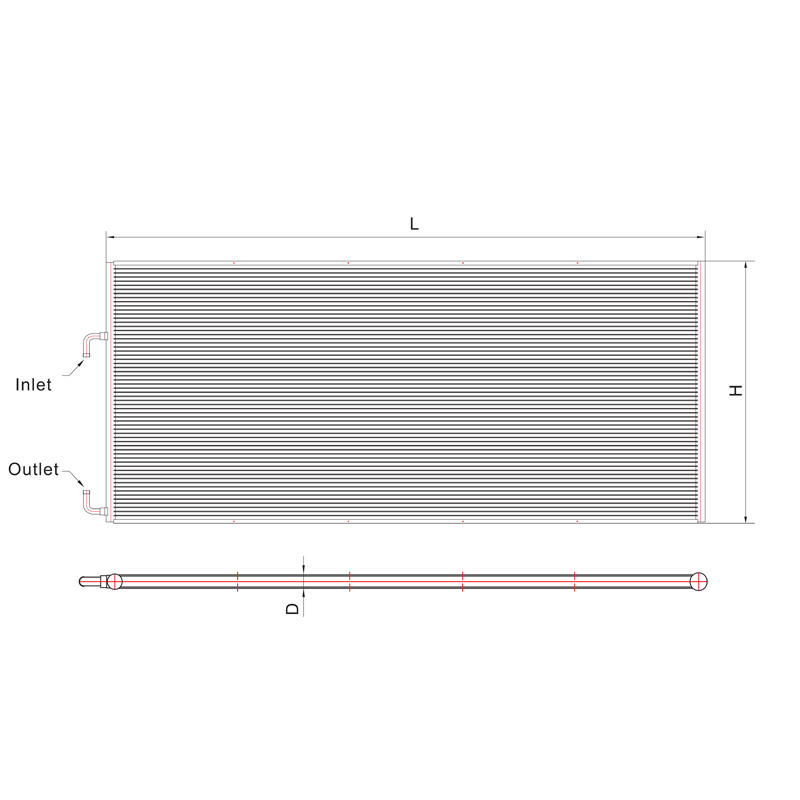

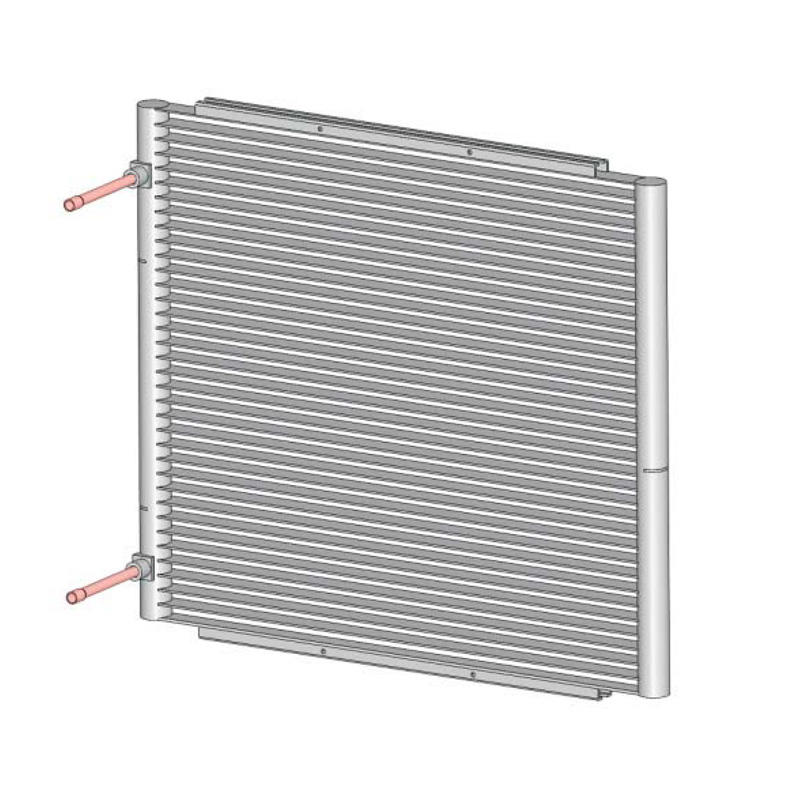

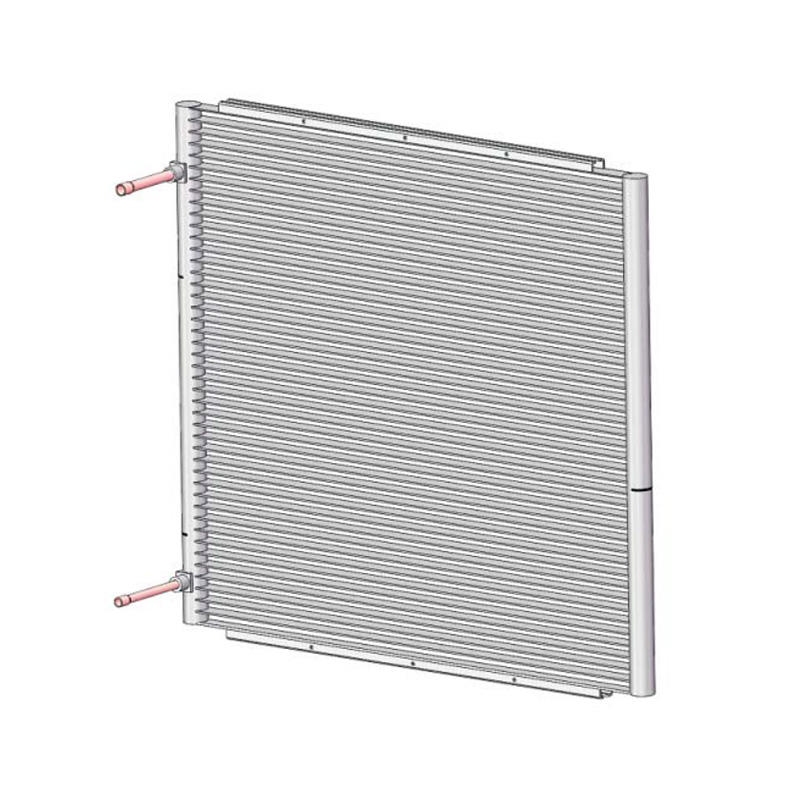

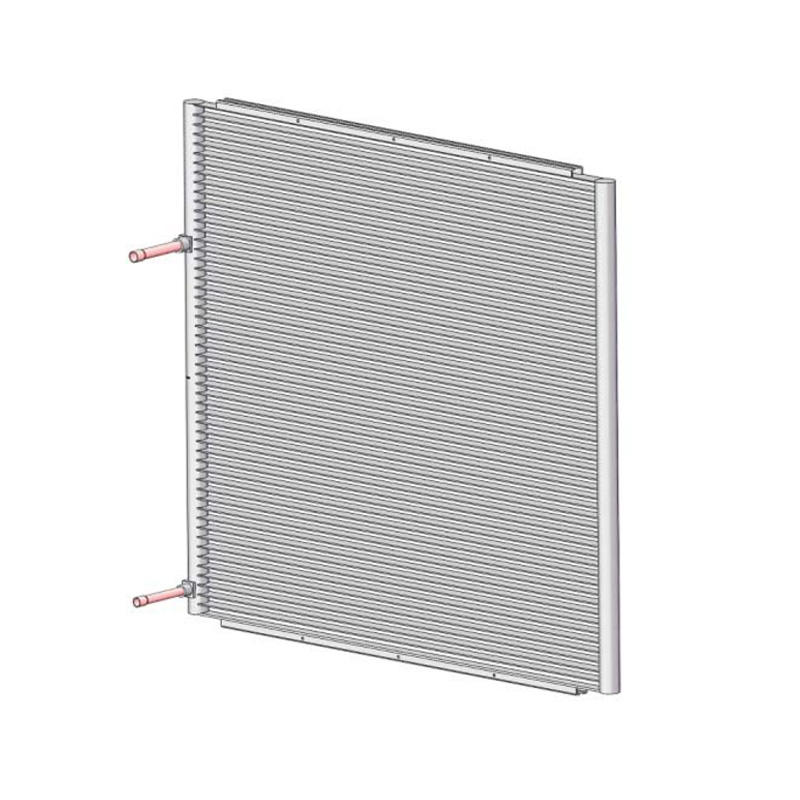

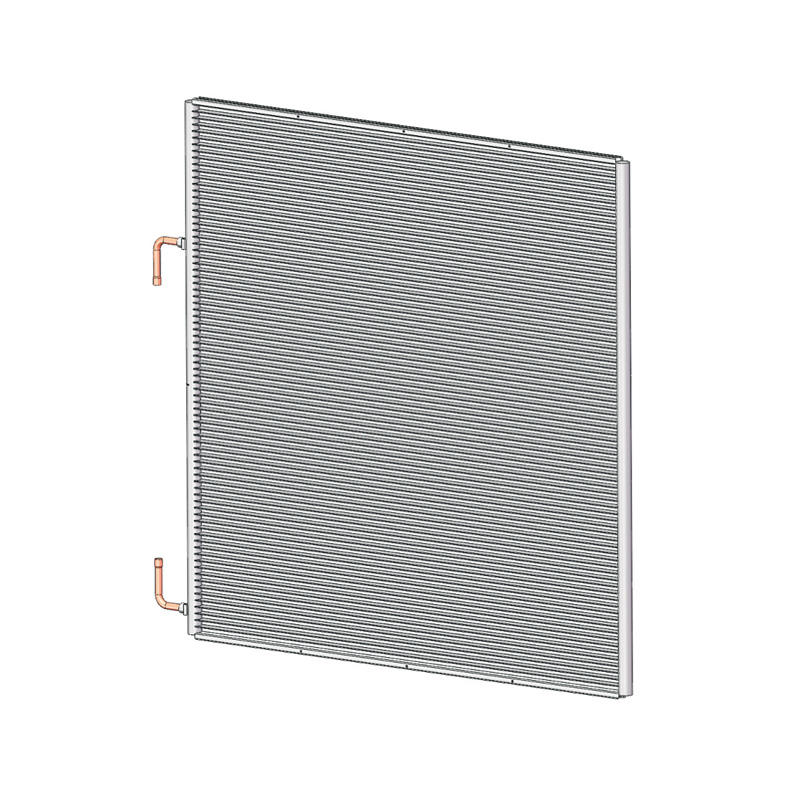

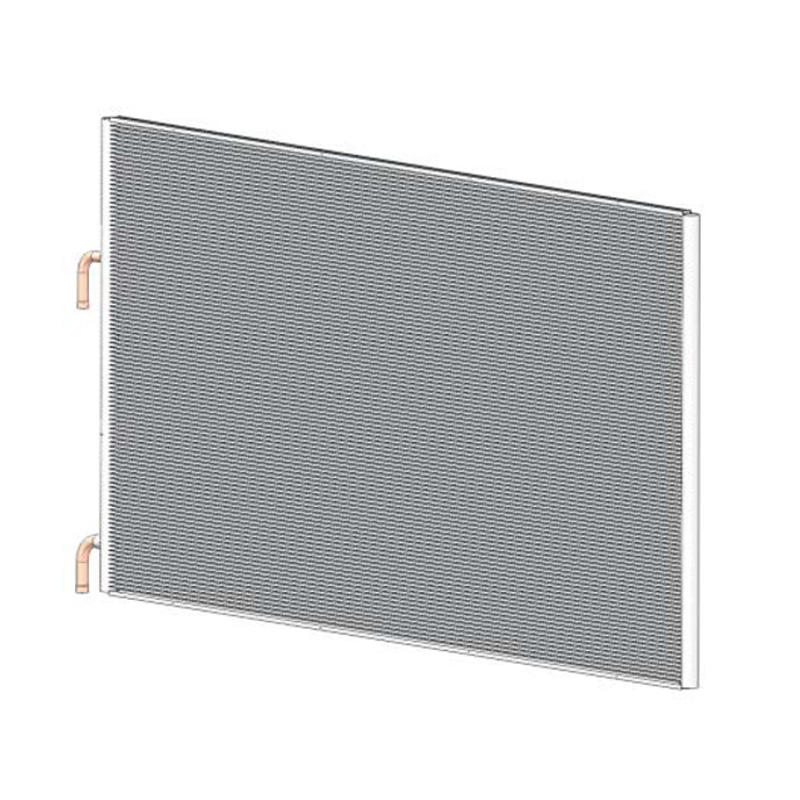

1. Micro-Channel Configuration: The SC-1500 condenser coil utilizes a micro-channel design, which consists of a couple of small channels through which the refrigerant or coolant flows. These channels are usually within the range of 0.5mm to 1.5mm in diameter. The gain of this design is that it extensively will increase the surface place to be had for heat trade. More surface location leads to a higher heat switch price, making the SC-1500 condenser coil greater green in transferring warmth.

2. Compact Size: The SC-1500 condenser coil is designed to be compact. The small dimensions of the condenser coil permit for green cooling in space-restricted programs. This is particularly useful in industries which include automobile, aerospace, and electronics, wherein equipment or additives want to be cooled within restricted area.

3. Multi-Port Design: The SC-1500 condenser coil is generally constructed with a multi-port design, which means that that a couple of refrigerant or coolant circuits are incorporated right into a unmarried coil unit. This layout optimizes the go with the flow distribution and guarantees a good distribution of refrigerant or coolant go with the flow across the coil. By frivolously distributing the glide, it allows to maximise heat switch efficiency and prevent any strain drops inside the system.

4. Corrosion-Resistant Materials: The SC-1500 condenser coil is generally synthetic the use of corrosion-resistant materials, which include aluminum or stainless-steel. These substances are selected for their ability to face up to harsh running situations, resist corrosion, and maintain their performance over the years. Using corrosion-resistant materials ensures sturdiness and reliability of the condenser coil, even if exposed to aggressive environments or corrosive fluids.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>