How does the coil period of 1280mm affect the performance of the SC-1600 Condenser Coil?

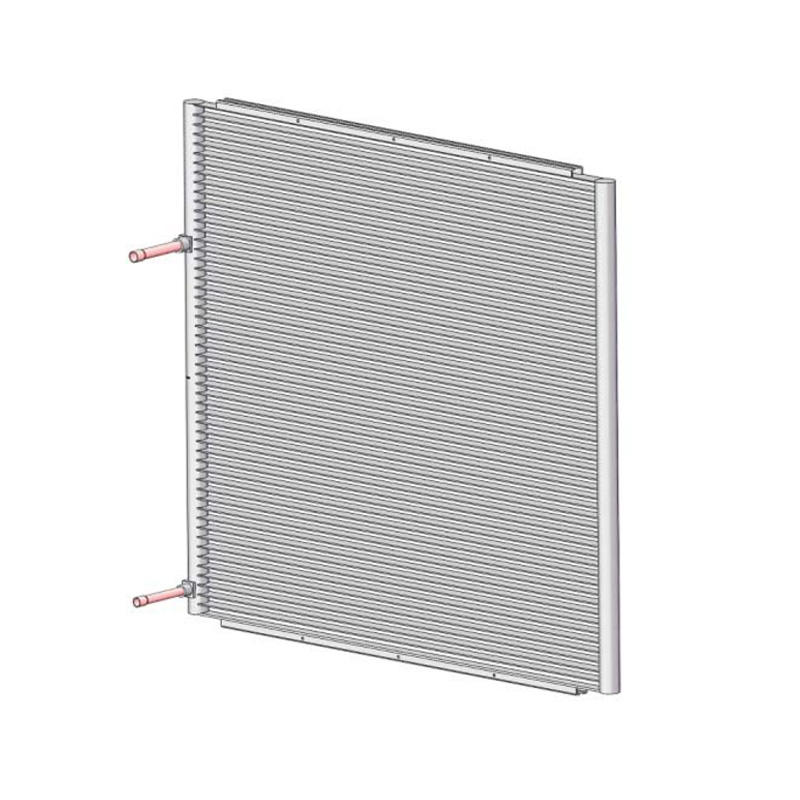

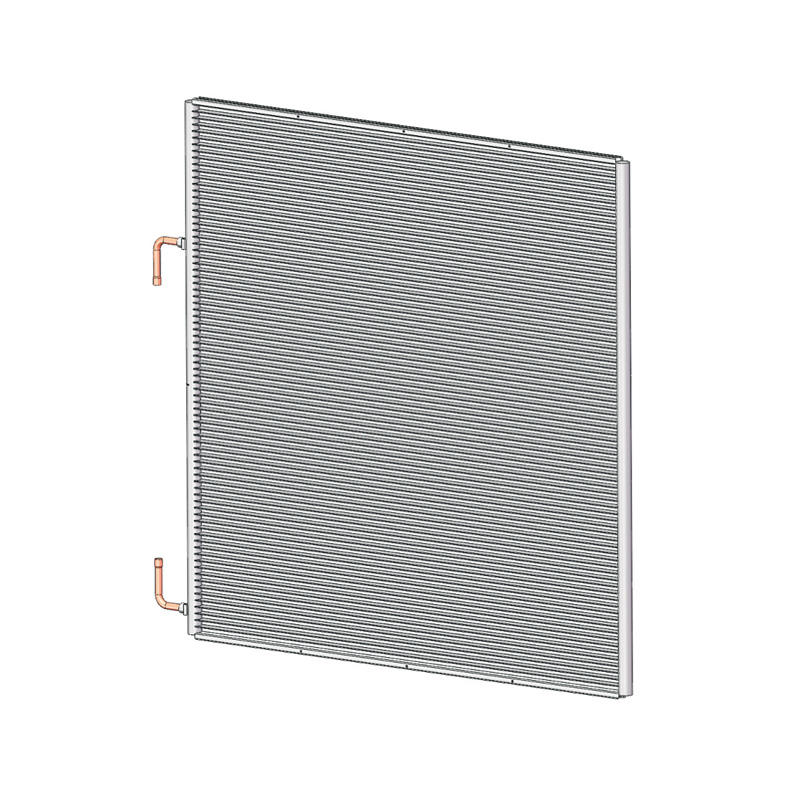

The condenser coil is a key issue of the heat exchanger machine in HVAC (heating, ventilation, and air conditioning) units. It is responsible for facilitating the transfer of heat from the refrigerant to the surrounding air outdoor the unit. The SC-1600 Condenser Coil utilizes micro-channel generation, which complements its performance and overall performance.

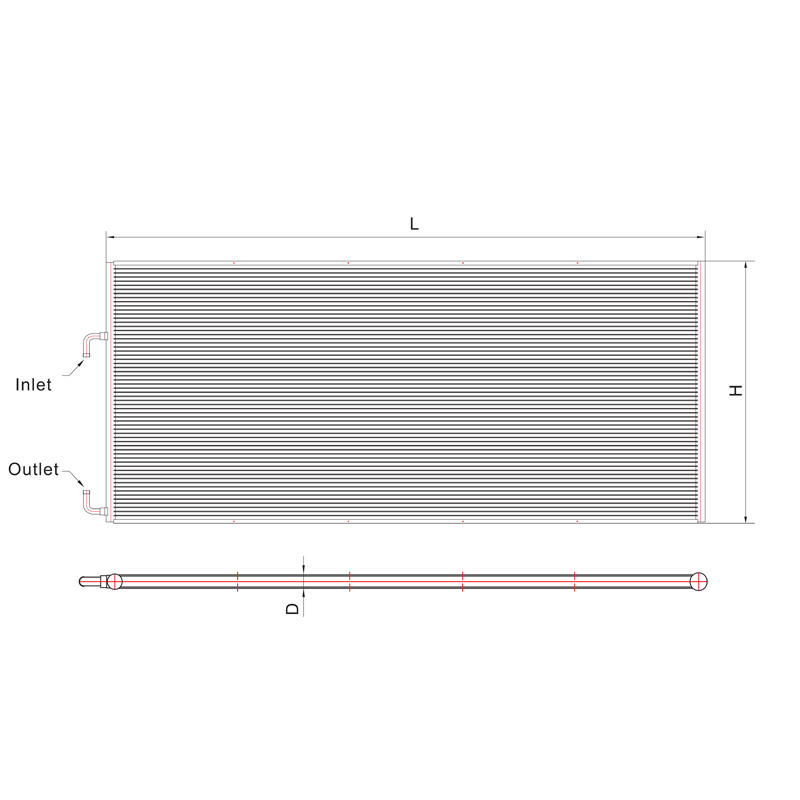

The coil length performs a vital function in determining the surface vicinity to be had for heat transfer. In trendy, a longer coil duration gives a bigger surface location, which will increase the heat transfer abilities of the condenser coil. This way that a longer coil can use up greater heat and enhance the overall efficiency of the gadget.

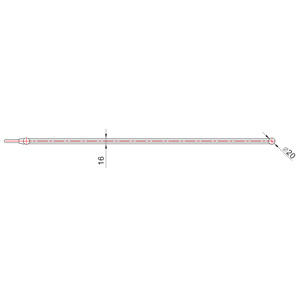

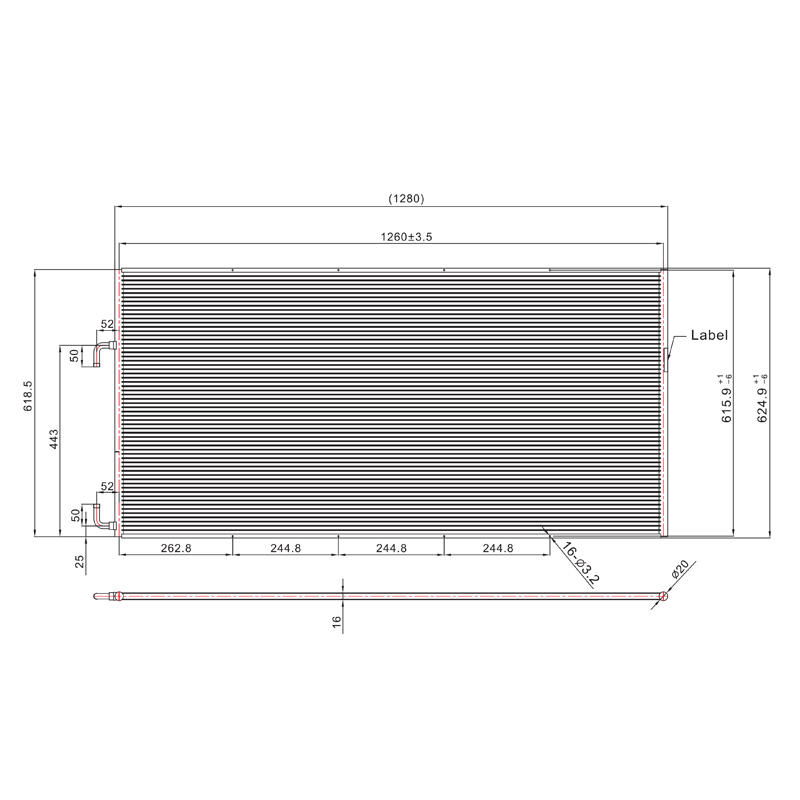

With a coil length of 1280mm, the SC-1600 Condenser Coil is designed to maximise the heat switch method. The expanded surface region lets in for greater heat alternate between the refrigerant flowing via the coil and the ambient air. This outcomes in higher cooling talents, that is in particular important in high-call for programs or regions with warm climates.

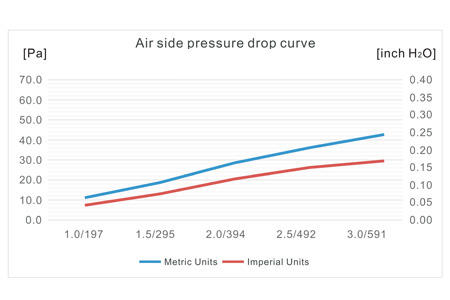

A longer coil length additionally helps better airflow across the coil, decreasing any capability pressure drops or airflow restrictions. This promotes superior heat transfer by means of making sure efficient air movement and minimizing any resistance that might avert the performance of the condenser coil.

Moreover, the precise coil duration of 1280mm can be selected primarily based at the layout concerns and necessities of the system it's miles supposed for. The length is probable determined through research, checking out, and to make certain that it gives the gold standard balance among heat switch efficiency and area constraints.

However, it's miles critical to note that at the same time as an extended coil duration can offer benefits in terms of heat switch, it additionally has realistic boundaries. As the coil length will increase, it necessitates a larger bodily space for installation. HVAC devices in numerous applications might not constantly have sufficient area for accommodating longer coils. Hence, there needs to be a cautious attention of the precise requirements and constraints of the machine at the same time as determining the coil length.

What materials are used in the production of the SC-1600 Condenser Coil Micro-Channel Heat Exchanger?

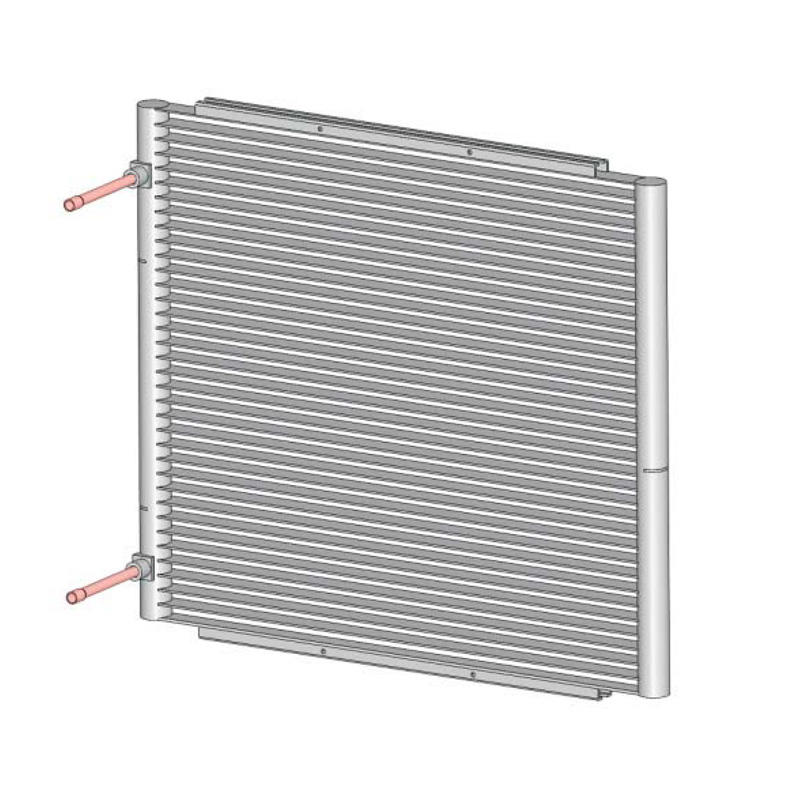

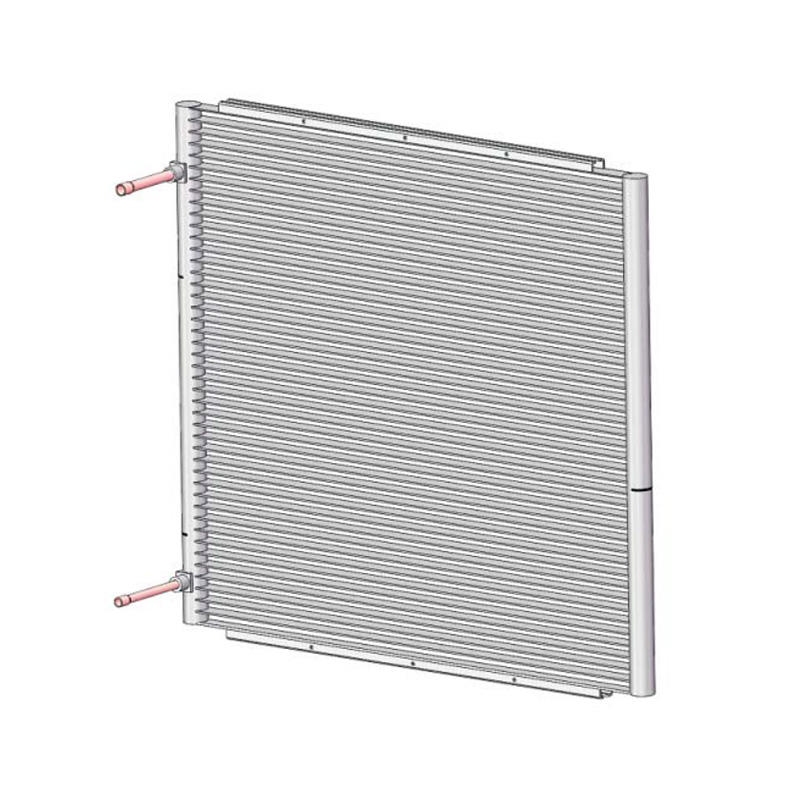

The SC-1600 Condenser Coil Micro-Channel Heat Exchanger is designed with remarkable materials to make sure long-lasting and green performance. The construction of this heat exchanger involves the usage of diverse additives every serving a selected motive to optimize heat switch and usual capability.

One of the primary substances used within the production of the SC-1600 Condenser Coil is aluminum. Aluminum is usually chosen for its exceptional thermal conductivity homes, making an allowance for efficient heat transfer among the refrigerant and the encompassing air. Additionally, aluminum is lightweight, corrosion-resistant, and sturdy, making it a perfect fabric for heat exchanger applications.

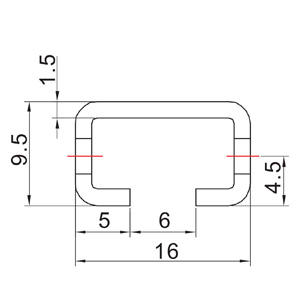

The micro-channel era in the SC-1600 Condenser Coil is typically carried out thru the use of aluminum tubes with small internal channels. These micro-channels offer an extended floor region for heat trade and allow more suitable heat transfer performance. The creation of the micro-channels calls for particular engineering to make sure the foremost flow of refrigerant and maximize heat alternate efficiency.

In addition to aluminum, different materials also are utilized within the construction of the SC-1600 Condenser Coil. Copper is usually used for the headers and connections of the heat exchanger because of its extremely good thermal conductivity and corrosion resistance. Copper gives a dependable and efficient pathway for the refrigerant go with the flow the heat exchanger.

To in addition enhance the corrosion resistance of the heat exchanger, a protective coating or surface remedy frequently implemented. One common floor remedy is the utility of a hydrophilic coating, which promotes water drainage and forestalls the formation of water droplets on the surface of the coils. This coating improves normal heat transfer overall performance and reduces the capability for corrosion.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>