How does the excessive thermal conductivity of aluminum in tube and fin configurations make a contribution to the efficiency of heat dissipation in car cooling structures, and what impact does it have on basic vehicle performance and gasoline performance?

The high thermal conductivity of Aluminum Tube Aluminum Fin Heat Exchanger plays a crucial function in enhancing the efficiency of heat dissipation in car cooling structures. Here's how it contributes to normal vehicle overall performance and gas efficiency:

1. **Effective Heat Transfer:**

- Aluminum's high thermal conductivity allows for speedy heat switch between the new engine coolant flowing through the tubes and the surrounding air passing over the fins. This green warmth switch is critical for preventing the engine from overheating all through operation.

2. **Improved Cooling System Efficiency:**

- The use of aluminum tubes and fins increases the floor place to be had for warmth trade. This larger surface vicinity, coupled with aluminum's capacity to behavior heat efficiently, improves the effectiveness of the cooling device in dissipating heat generated by using the engine.

3. **Reduced Weight:**

- Aluminum is a light-weight material in comparison to alternatives like copper or brass. The reduced weight of the heat exchanger contributes to decrease usual vehicle weight. This weight reduction is particularly essential in automobile design, as it can enhance gasoline performance and ordinary automobile performance.

4. **Enhanced Thermal Performance:**

- The excessive thermal conductivity of aluminum enables keep a more constant and controlled temperature inside the engine. This is essential for optimizing combustion performance, minimizing thermal stress on engine additives, and making sure that the engine operates inside its greatest temperature range.

5. **Improved Fuel Efficiency:**

- Efficient warmth dissipation and temperature manage make contributions to higher engine efficiency. When the engine operates at an most advantageous temperature, it could obtain higher gasoline combustion performance, main to stepped forward gasoline financial system and decreased emissions.

6. **Durability and Corrosion Resistance:**

- Aluminum's durability and corrosion resistance make sure that the heat exchanger maintains its overall performance through the years, even in difficult car environments. This durability contributes to the general reliability of the cooling system and, therefore, the car's overall performance.

7. **Space Efficiency:**

- Aluminum Tube Aluminum Fin Heat Exchangers can be designed with a compact shape thing, optimizing area inside the engine compartment. This area efficiency is valuable in contemporary automobile layout, in which compact and light-weight additives are vital for maximizing fuel performance without sacrificing overall performance.

In precis, the excessive thermal conductivity of aluminum in tube and fin configurations allows green warmness dissipation in automobile cooling structures. This, in turn, definitely influences typical vehicle overall performance by keeping gold standard engine temperatures, reducing weight, and enhancing fuel performance.

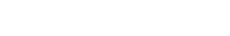

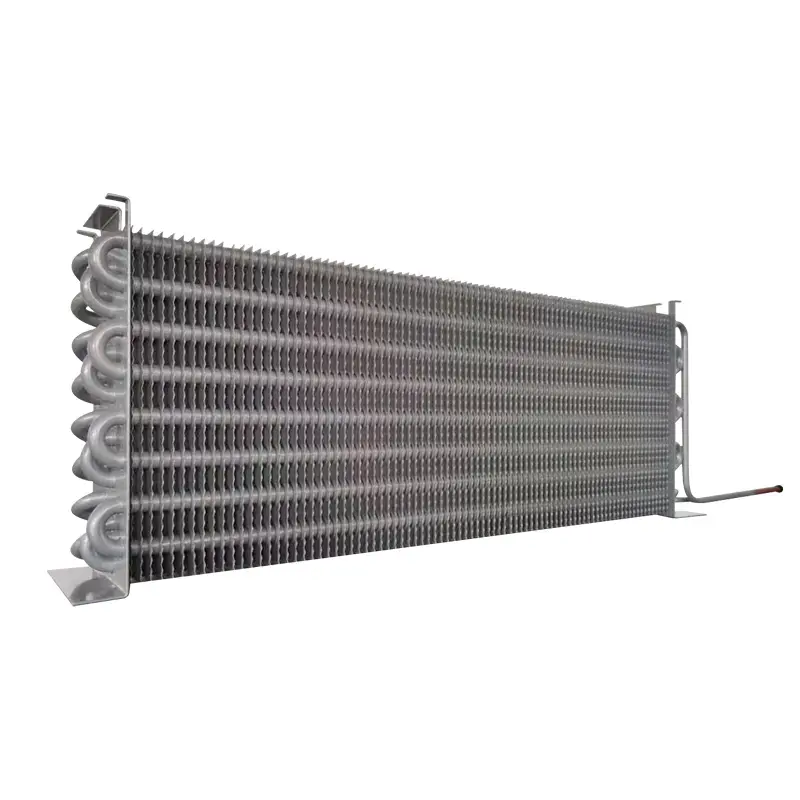

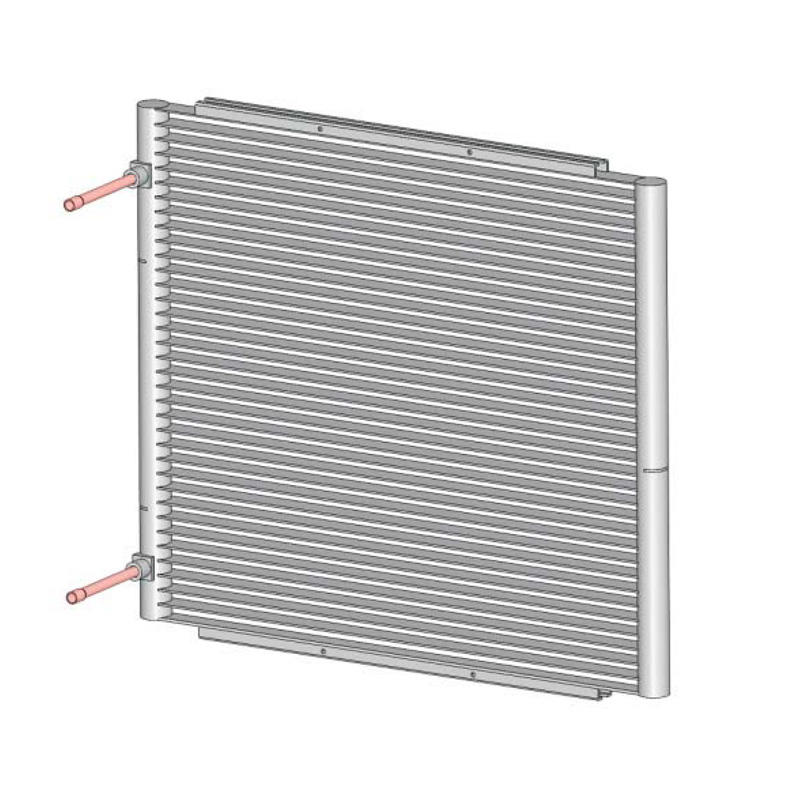

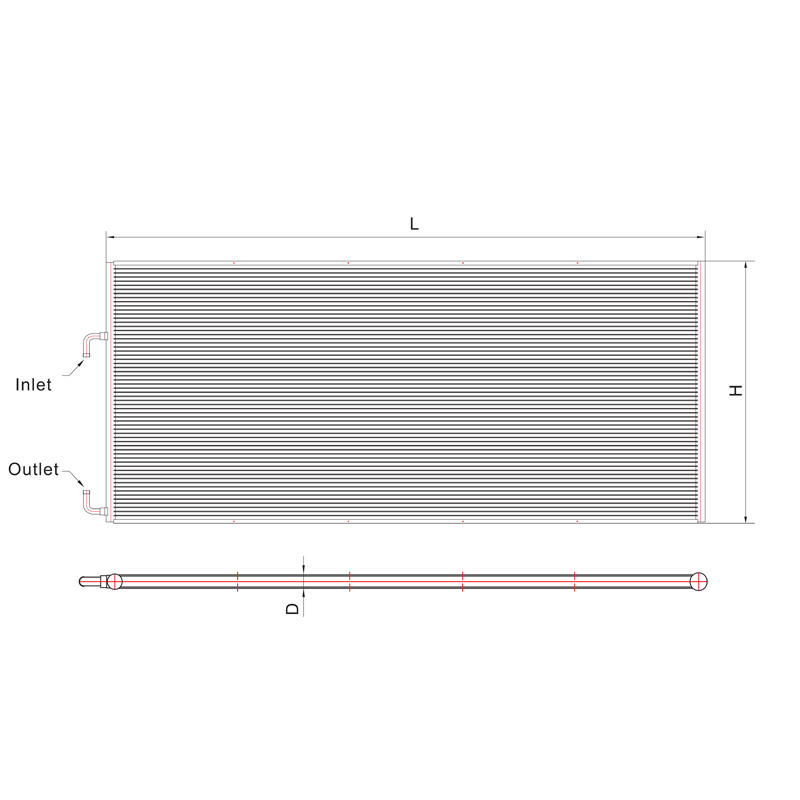

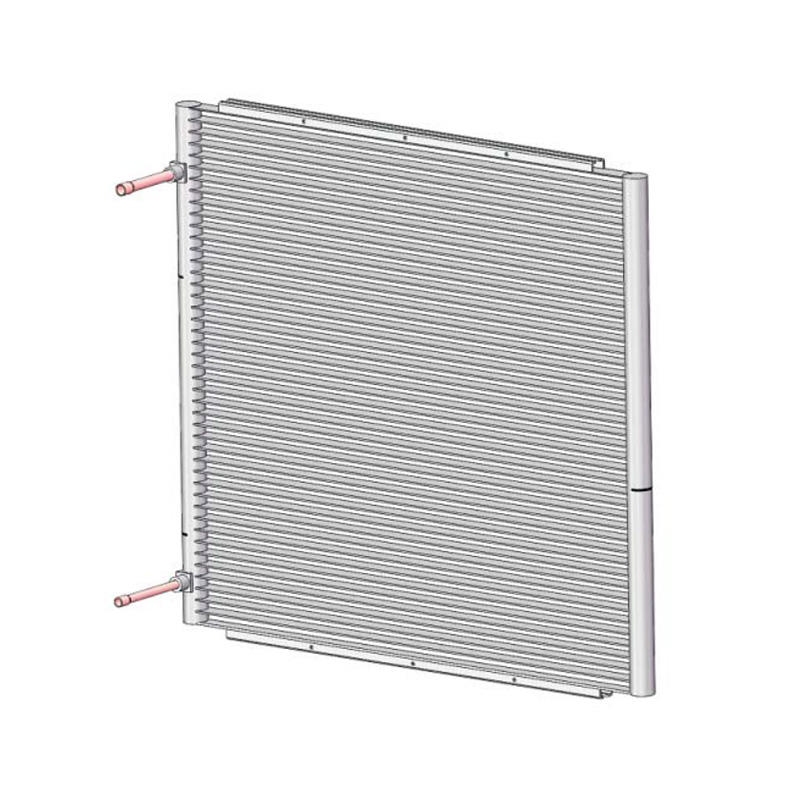

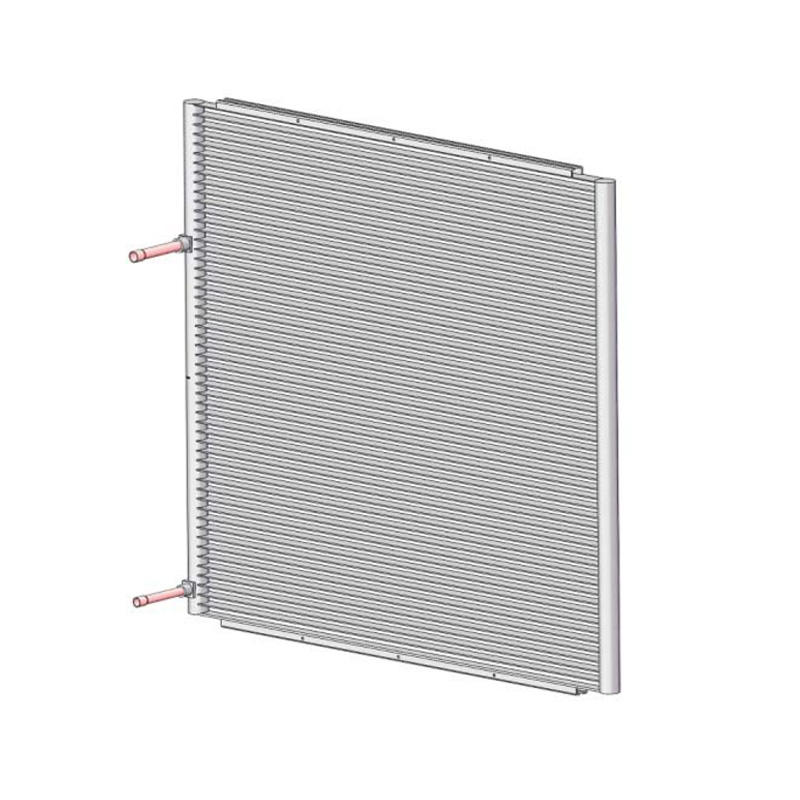

Aluminum Tube Finned Tube Heat Exchanger

Aluminum Tube Finned Tube Heat Exchanger

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>