In the process of oil and natural gas extraction, it is often necessary to handle high-pressure and high-temperature fluids, which places high demands on the pressure-bearing capacity of the heat exchanger. Can the Micro Channel Heat Exchanger maintain stable performance in this high-pressure environment?

Whether a Micro Channel Heat Exchanger (MCHE) can maintain stable performance in a high-pressure, high-temperature fluid environment depends on the quality of its design and manufacturing. Here is some analysis of how MCHE might behave in this environment:

First of all, due to its microchannel design, MCHE has the characteristics of high heat transfer coefficient, high surface area to volume ratio, low heat transfer temperature difference and low flow resistance. These characteristics give MCHE significant advantages in heat exchange efficiency. However, these characteristics do not mean that MCHE can naturally withstand high pressure and high temperature environments.

In a high-pressure environment, the pressure-bearing capacity of MCHE mainly depends on its material selection, structural design and manufacturing process. If the MCHE uses high-strength, high-pressure-resistant materials, has a reasonable structural design and can withstand the impact of high-pressure fluid, and has excellent manufacturing processes and no manufacturing defects, then the MCHE is likely to maintain stable performance in a high-pressure environment.

In addition, MCHE's performance in high-temperature environments is also closely related to its material selection. High temperatures may cause material failure modes such as creep, oxidation, or thermal fatigue. Therefore, MCHE needs to select materials that can maintain strength and stability at high temperatures.

However, although the design and manufacture of MCHE may take into account the needs of high-pressure and high-temperature environments, in actual applications, other factors need to be considered, such as the corrosiveness of the fluid, flow rate, pressure fluctuations, etc., which may affect the performance of MCHE. performance impact.

Whether MCHE can maintain stable performance in high-pressure and high-temperature fluid environments depends on many factors such as its design, material selection, manufacturing process, and actual application conditions. Therefore, when selecting and using MCHE, these factors need to be considered comprehensively and fully tested and verified.

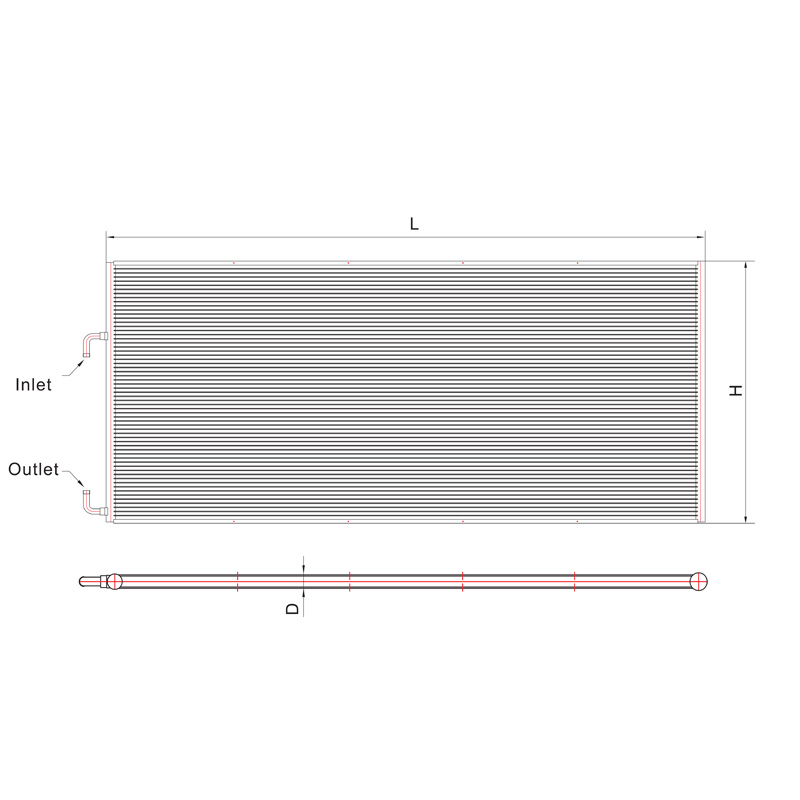

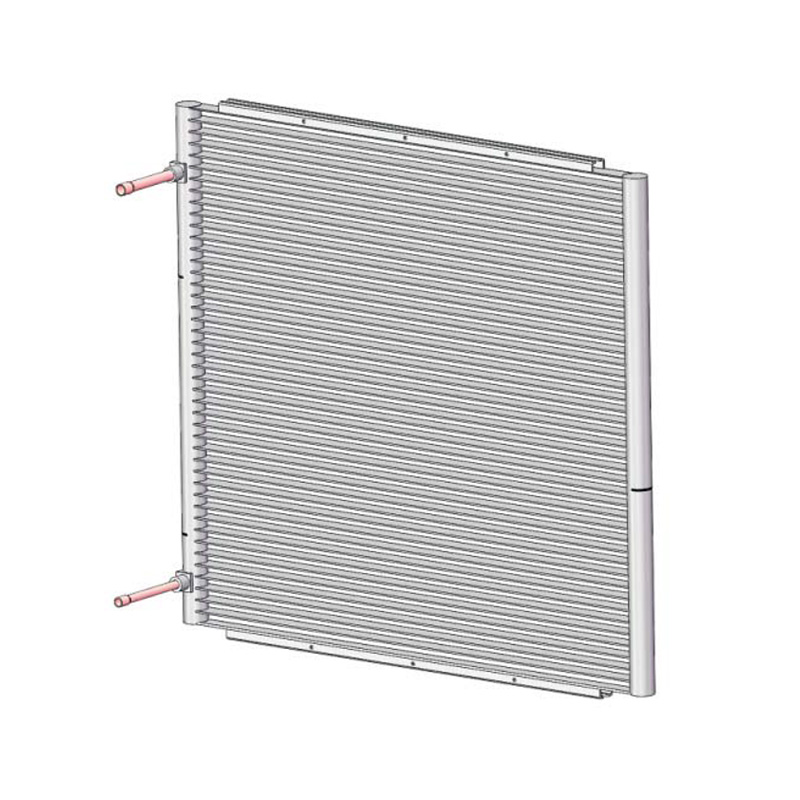

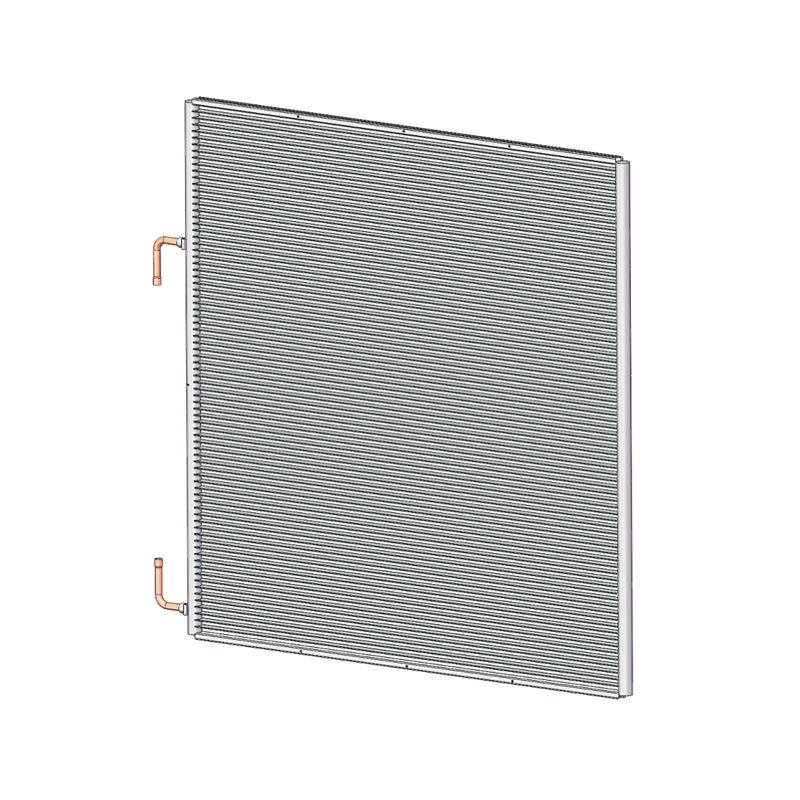

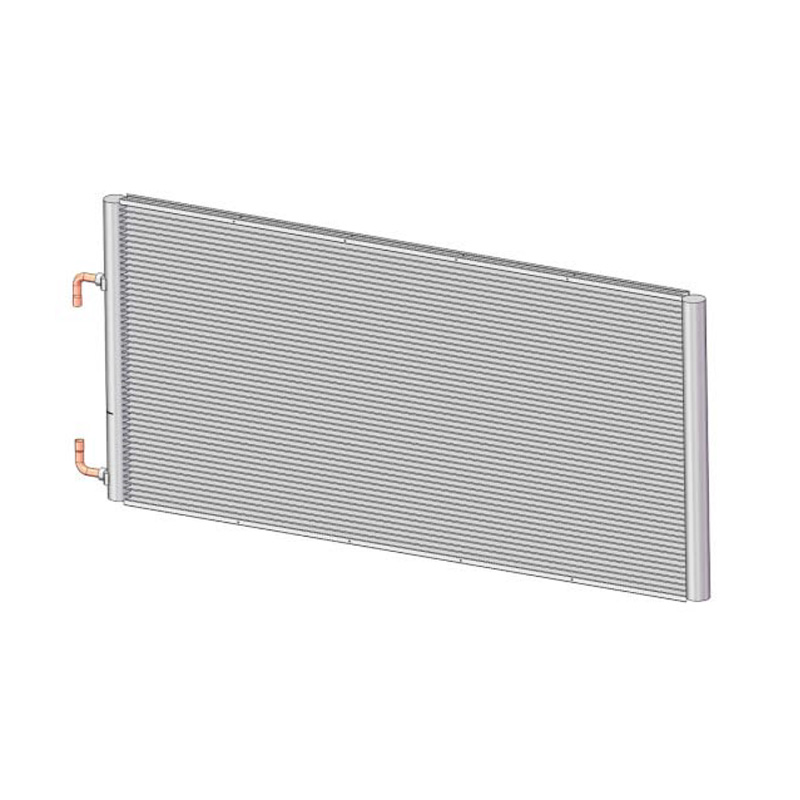

SC-1300 550*515.9mm Car/HVAC Microchannel Condenser Coil Micro Channel Heat Exchanger

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>