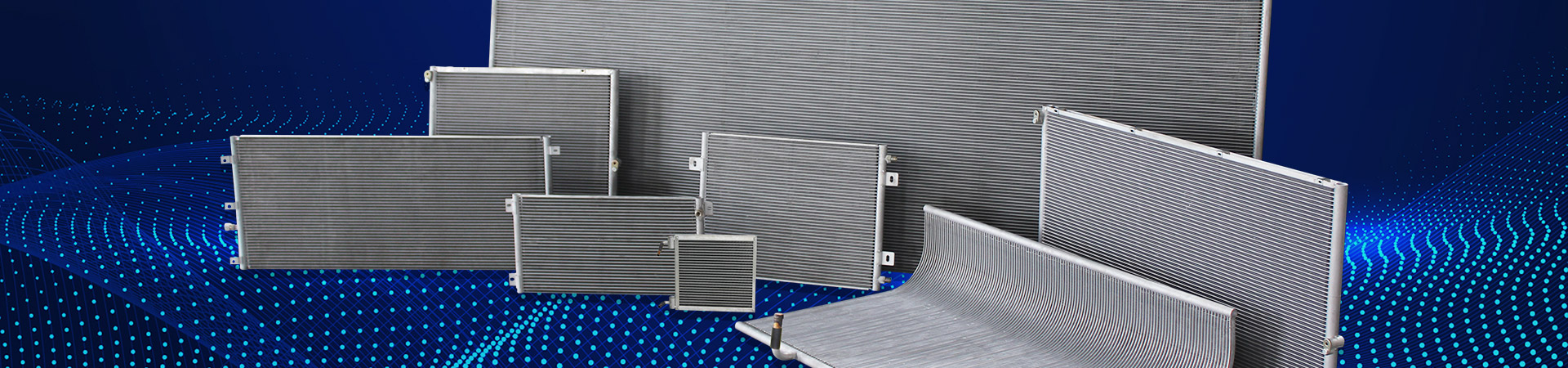

How does the micro-channel design of the SC-1700 Condenser Coil beautify the heat alternate technique?

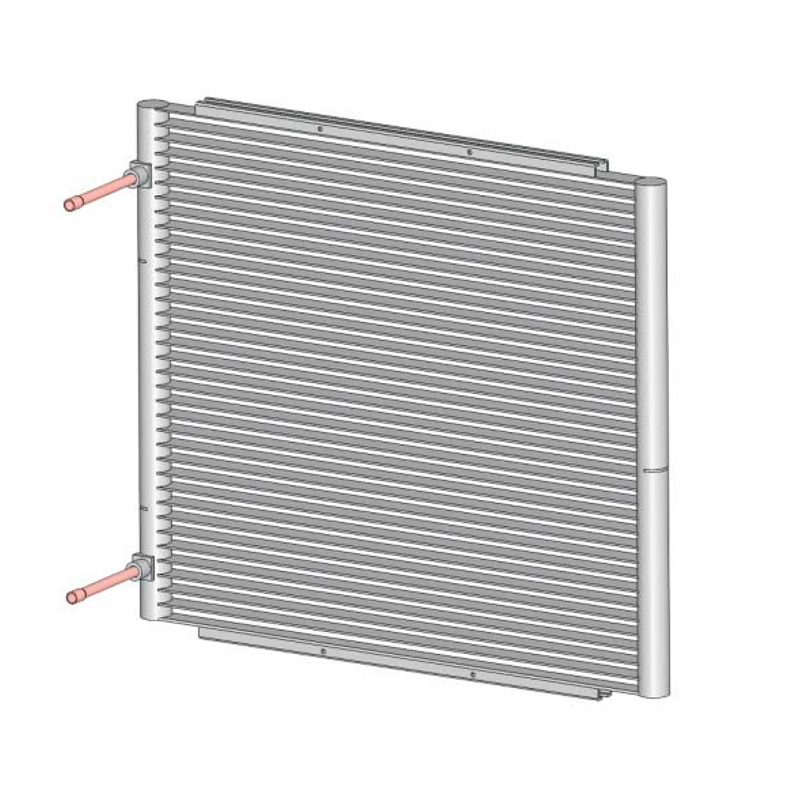

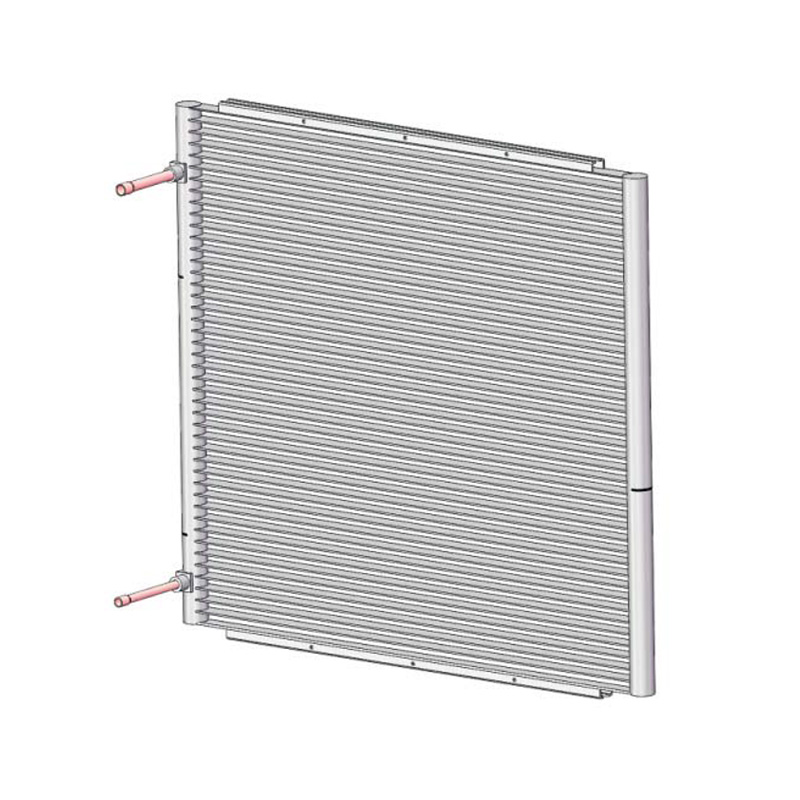

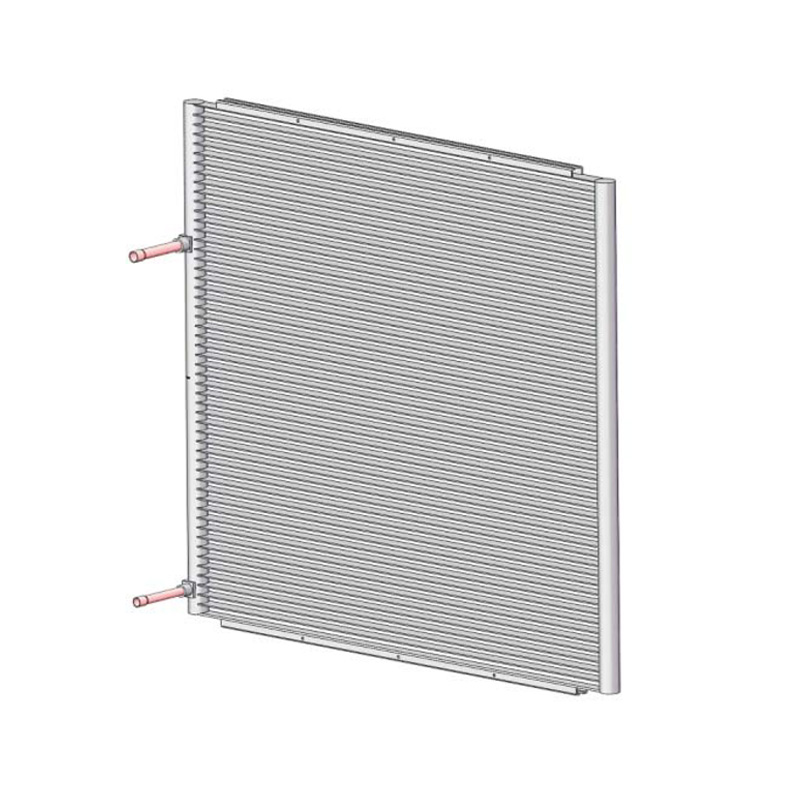

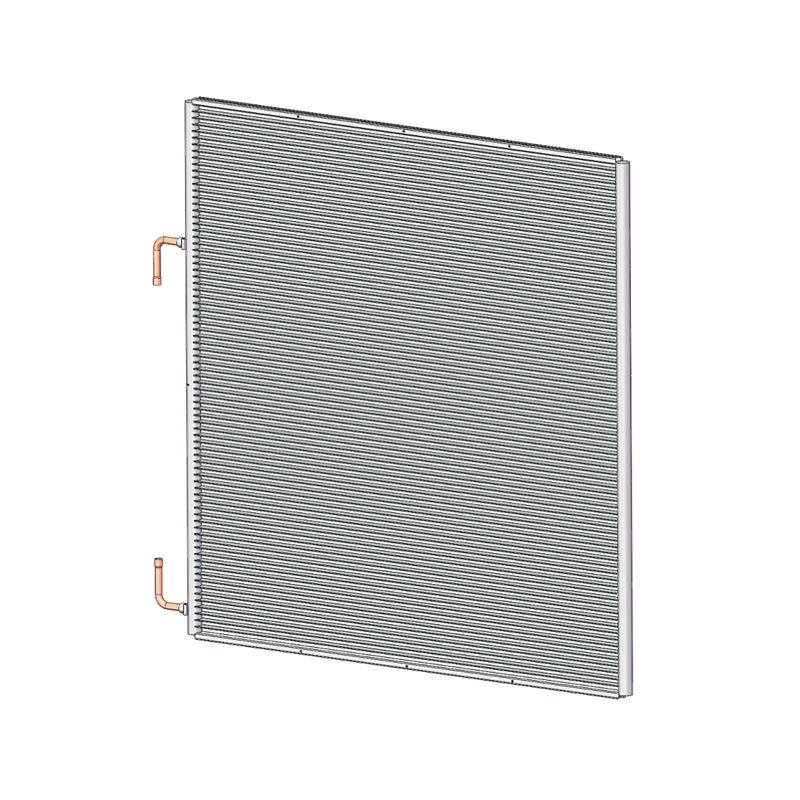

The micro-channel design of the SC-1700 Condenser Coil is a full-size development in heat exchanger generation. This particular layout consists of a couple of small channels or passages embedded inside the coil shape, which greatly complements the heat exchange method.

One of the principle advantages of the micro-channel design is its potential to growth the floor area available for heat switch. By incorporating numerous small channels, the full floor place exposed to the flowing fluid is notably accelerated in comparison to standard coil designs. This increased surface region allows for greater efficient heat switch, because it provides a bigger touch vicinity between the fluid and the coil.

The improved surface vicinity of the micro-channel design additionally improves the coil's heat switch coefficient. The heat transfer coefficient is a measure of how properly a material or floor can transfer heat, and a higher coefficient suggests a more green switch. The micro-channel design increases the contact between the fluid and the coil, main to higher convective heat transfer coefficients and advanced average heat switch performance.

Furthermore, the smaller size of the micro-channels lets in for more powerful heat switch with lower refrigerant price necessities. The decreased extent of refrigerant within the micro-channels leads to quicker and more uniform heat alternate, minimizing the potential for refrigerant mass accumulation and making sure solid and efficient cooling performance.

Another advantage of the micro-channel layout is its stepped forward heat and mass switch traits. Due to the decreased channel length, the fluid flowing the channels stories higher velocities, main to more desirable convective warmness transfer. This better speed additionally promotes better blending and distribution the fluid, resulting in more efficient warmness switch and reduced temperature variations throughout the coil.

The micro-channel layout of the SC-1700 Condenser Coil additionally offers advanced heat switch overall performance at lower airflow rates. Traditional coil designs frequently suffer from decrease heat switch efficiency at reduced airflow, but the micro-channel layout mitigates this problem through presenting a larger surface place and increased fluid turbulence within the channels. This guarantees most useful heat transfer even at decrease airflow conditions, making the SC-1700 Condenser Coil suitable for diverse packages with various airflow necessities.

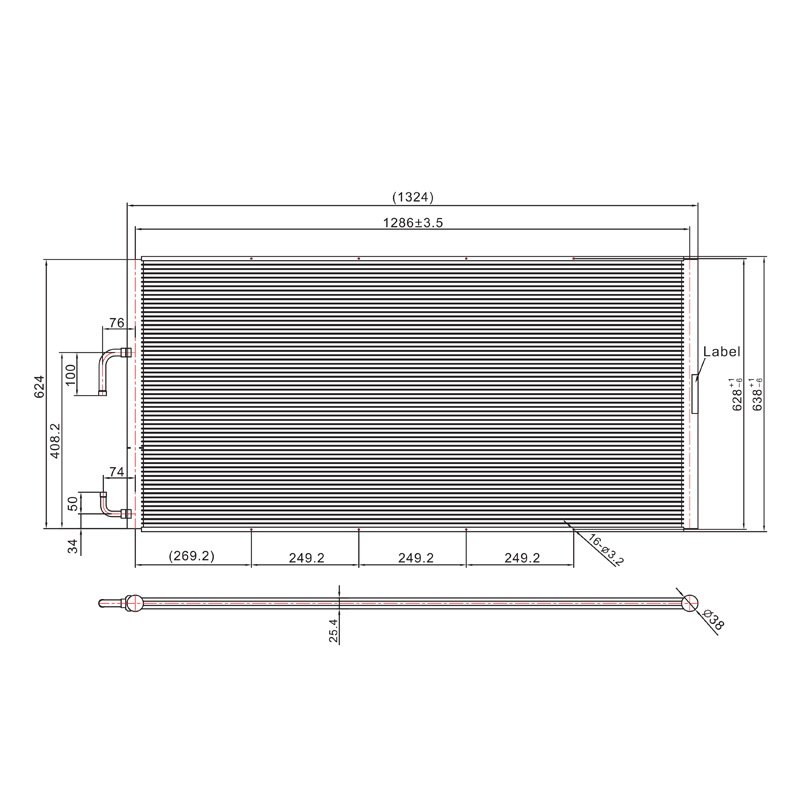

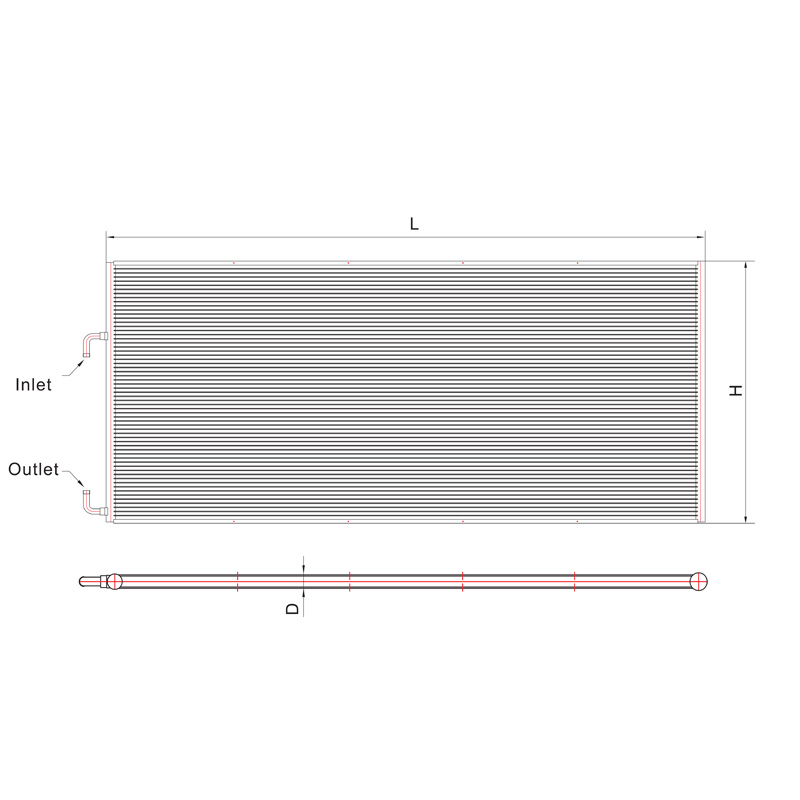

What are the key blessings of the use of a 638mm coil peak inside the SC-1700 Condenser Coil?

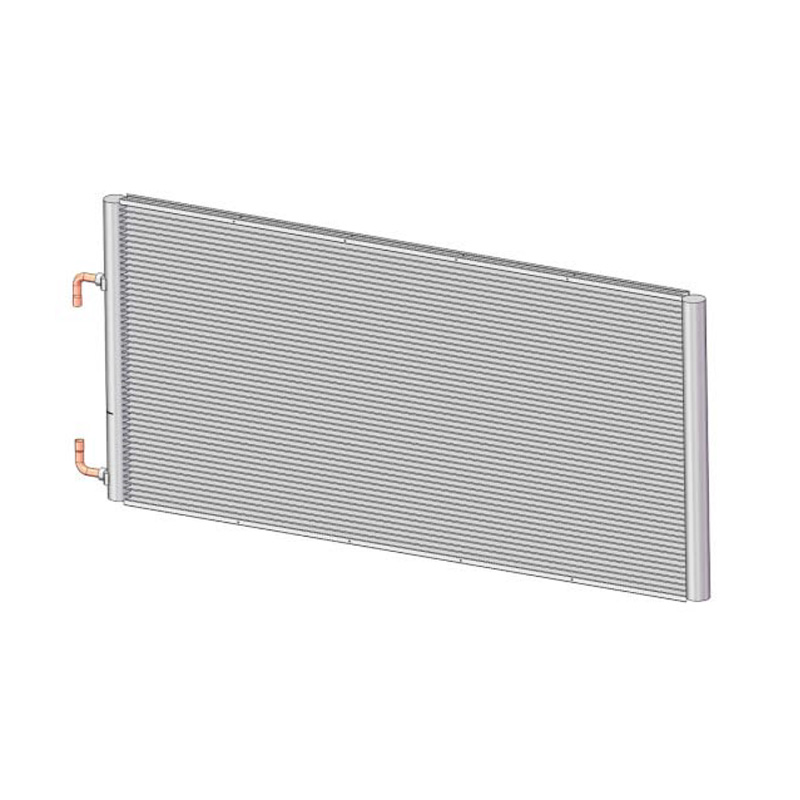

1. Increased Heat Transfer Surface Area: The 638mm coil height permits for a greater floor place within the condenser coil, which directly affects the heat transfer system. With more floor location, there may be a larger area to be had for heat trade between the refrigerant and the encircling environment. This ends in progressed normal performance and efficiency of the cooling device.

2. Higher Heat Transfer Rate: A taller coil height lets in for an extended flow course for the refrigerant within the coil. As a result, the refrigerant has greater time to change heat with the encompassing air or fluid. This results in a higher heat switch rate, which means that the condenser coil can dispose of heat from the refrigerant greater efficiently. Consequently, this will increase the cooling potential of the machine and allows for greater temperature differentials.

3. Improved Airflow Distribution: The accelerated coil height presents extra room for the air or fluid to float thru the coil. This enables to make certain a extra even airflow distribution across the coil, reducing the likelihood of hotspots or regions with decreased heat transfer. With improved airflow distribution, the condenser coil can attain a more green and uniform cooling system.

4. Enhanced Heat Dissipation: The taller coil top also lets in for better heat dissipation. As the refrigerant exchanges heat with the encircling surroundings, the taller coil peak affords a bigger surface location for the warmth to be dissipated into the air or fluid. This consequences in a extra effective elimination of heat from the machine, that is crucial for maintaining the favored temperature degrees and preventing overheating.

5. Compact Design: Despite the accelerated coil peak, the SC-1700 Condenser Coil continues to be designed to be compact and space-green. This is especially superb in installations with restricted space. The compact design ensures that the condenser coil may be incorporated into numerous structures, consisting of air con devices or refrigeration structures, without compromising on performance.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>