How does the coil depth of 25.4mm have an effect on the efficiency of the heat exchanger?

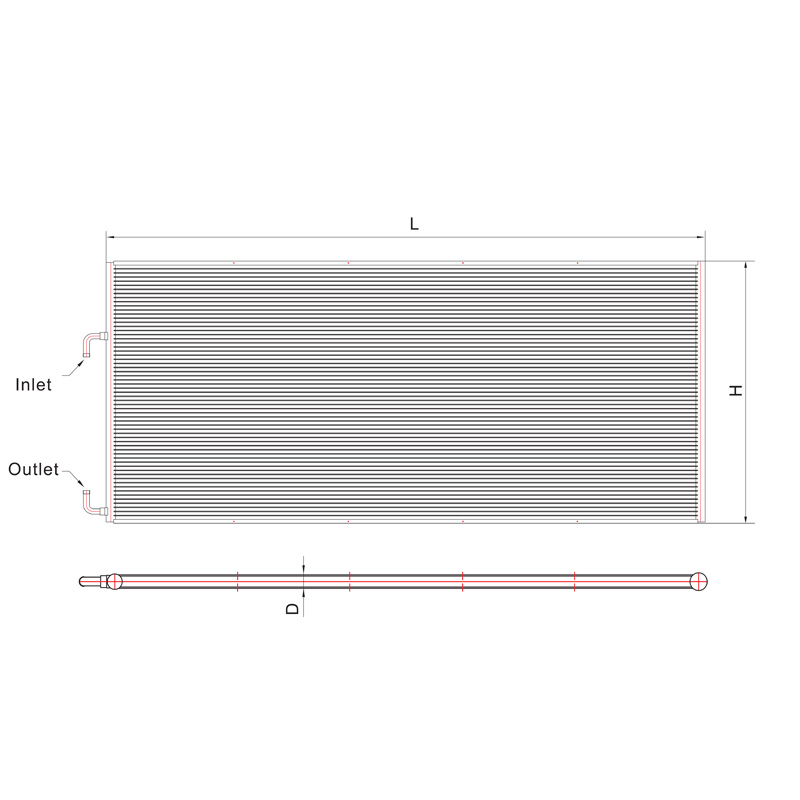

Firstly, it's far important to realise the basics of a heat exchanger. Heat exchangers are devices designed to switch thermal strength between fluids or materials at temperatures. They are generally used in numerous programs, consisting of air conditioning, refrigeration structures, and heat recuperation methods.

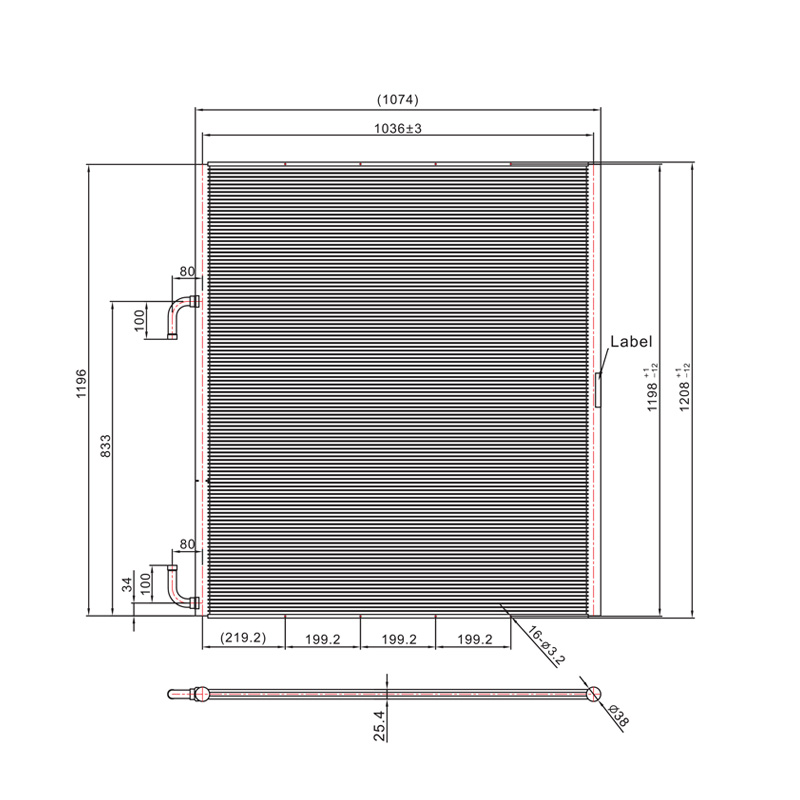

The coil intensity refers to distance between the front and back floor of the coil. In this situation, a coil depth of 25.4mm indicates that the gap between the back and front floor is 25.4mm. The coil depth, combined with other elements including coil surface region and fluid glide price, appreciably impacts the warmth transfer efficiency of the exchanger.

One key aspect encouraged by way of the coil intensity is the available surface region for heat switch. A extra coil intensity generally translates into a bigger surface area, which results in progressed heat transfer capabilities. This multiplied floor location allows for greater contact between the fluid flowing via the coil and the encircling surroundings. As a end result, heat is transferred greater correctly, leading to higher thermal efficiency.

Furthermore, a coil depth of 25.4mm allows for a higher range of fluid channels within the heat exchanger. Micro-channels, because the name shows, are extremely small channels in the coil, typically on the order of micrometers. These channels permit a extra floor location-to-quantity ratio, promoting efficient heat transfer due to extended touch among the fluid and the heat change surfaces.

Additionally, the coil intensity influences the fluid glide traits within the heat exchanger. A deeper coil regularly allows for a extra uniform distribution of the fluid across the channel surfaces, lowering the opportunity of hotspots and permitting a more balanced heat transfer. The improved glide distribution aids in maximizing the utilization of the whole coil floor and enhances the general efficiency of the heat exchanger.

It is well worth bringing up that the coil depth must be optimized primarily based at the unique application necessities. While a deeper coil may additionally provide blessings in terms of heat transfer, it also effects in accelerated stress drop due to better fluid resistance. Therefore, careful attention have to accept to strike a stability among accomplishing efficient heat transfer and minimizing pressure loss.

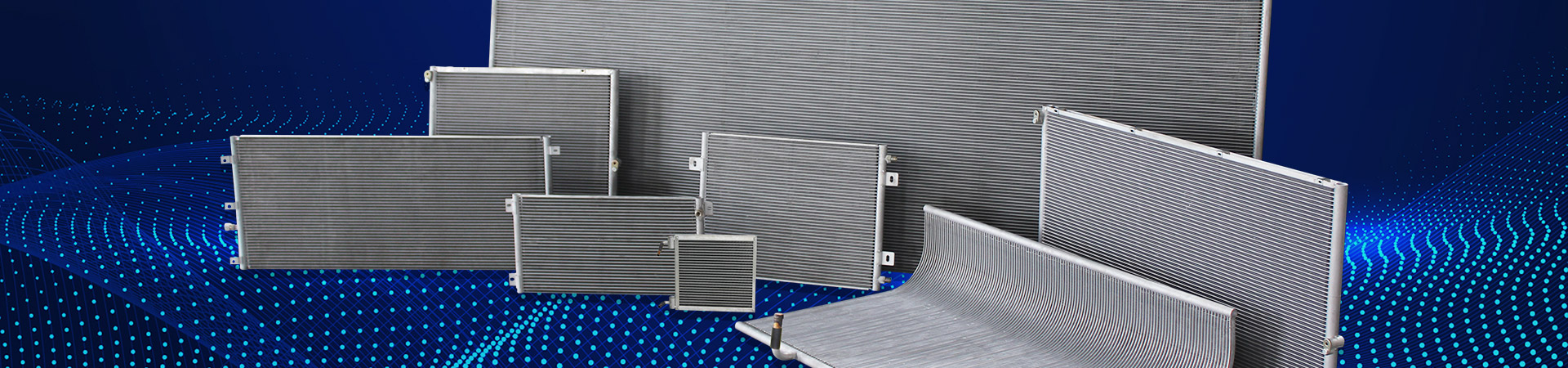

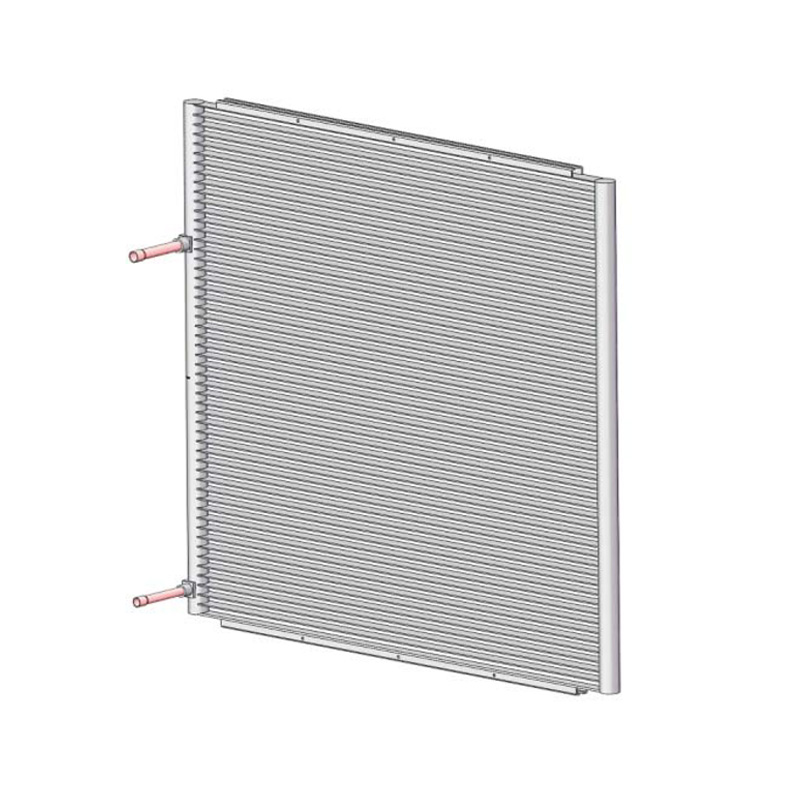

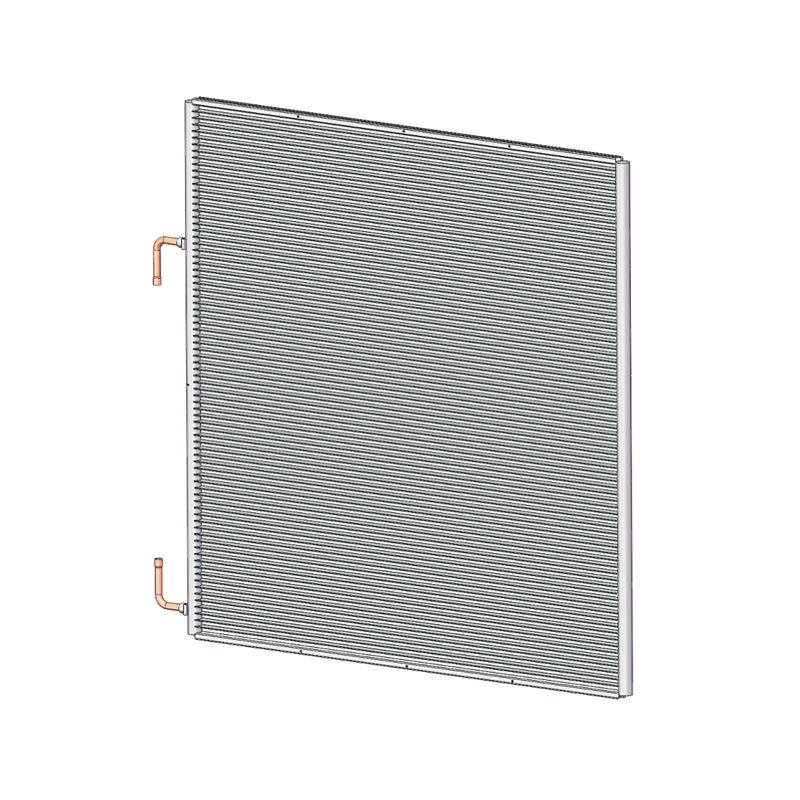

How does the design of the SC-1800 condenser coil micro-channel heat exchanger enhance warmth transfer skills?

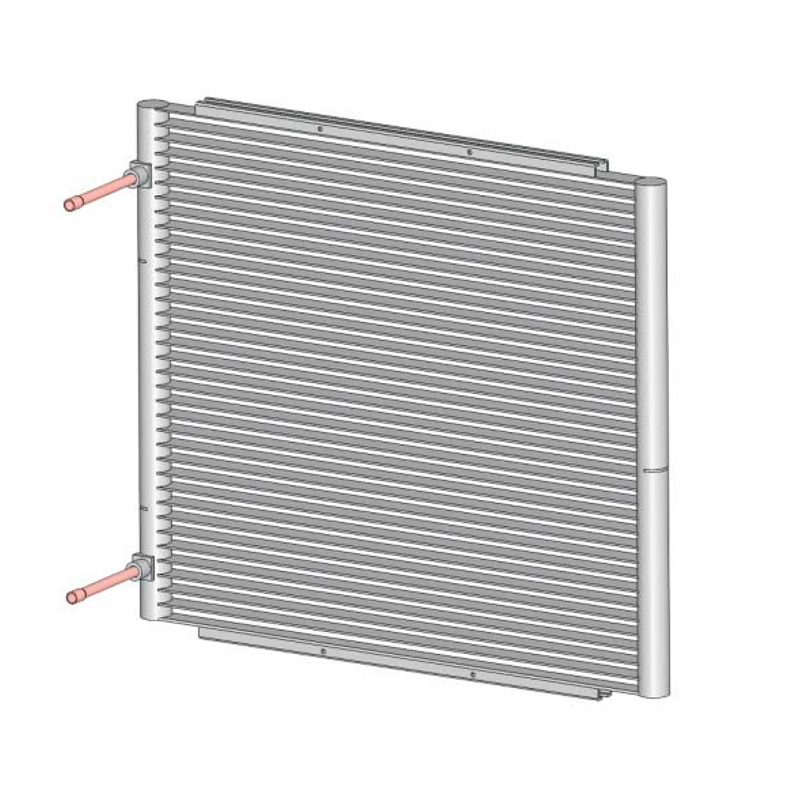

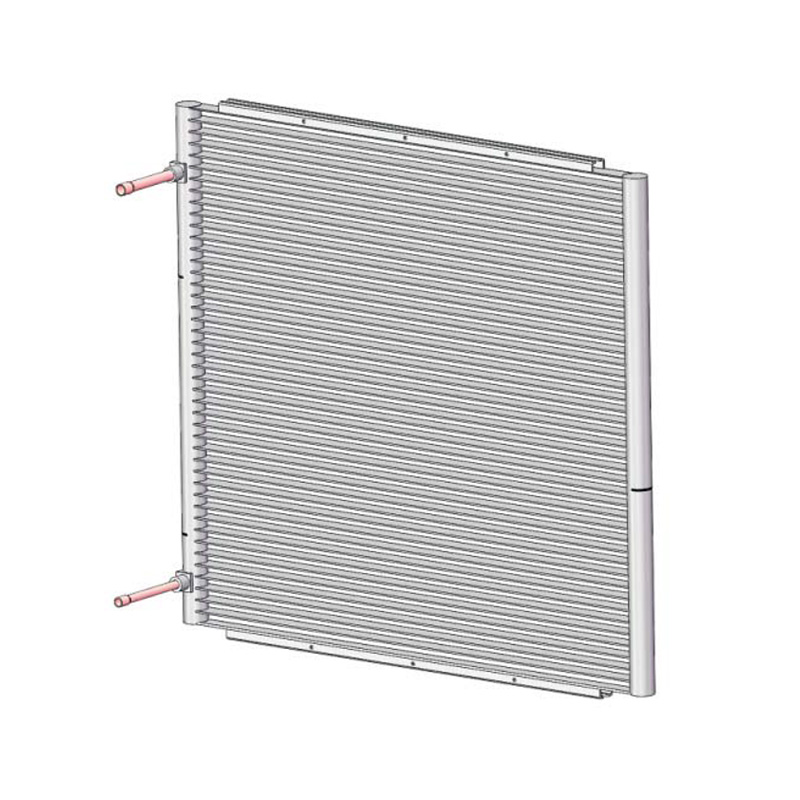

1. Micro-Channel Configuration: The SC-1800 condenser coil utilizes a micro-channel configuration, which includes more than one small channels or tubes that allow for a bigger heat transfer floor area. This improved surface region lets in for more contact between the heat exchanger and the fluid, facilitating more green heat switch.

2. Reduced Size: The micro-channel design permits a extensive reduction inside the length of the heat exchanger. This reduction in size enhances heat transfer by using reducing the gap between heat switch fluid and the stable wall of the channels. The reduced size also minimizes the strain drop, leading to elevated efficiency.

3. Enhanced Turbulent Flow: The micro-channels within the SC-1800 heat exchanger induce a turbulent float of the heat transfer fluid. Turbulent drift complements heat transfer by using constantly agitating the fluid, ensuring efficient change of thermal electricity among the fluid and the heat exchanger surface.

4. Optimal Fin Geometry: The SC-1800 condenser coil incorporates optimized fin geometry, which plays a important position in improving heat switch. The fins are designed to enhance the floor area to be had for heat change whilst additionally retaining a balanced stress drop across the channels. This design reduces the resistance to fluid waft, increasing heat switch efficiency.

5. High Thermal Conductivity Materials: The SC-1800 heat exchanger is built the use of materials high thermal conductivity, consisting of copper or aluminum. These substances have extremely good heat transfer residences, allowing for efficient transfer of thermal strength between the fluid and the heat exchanger surfaces.

6. Counterflow or Crossflow Arrangement: The SC-1800 heat exchanger can be designed with both counterflow and crossflow arrangements, depending on the specific utility. These preparations allow most excellent heat transfer through ensuring efficient temperature gradients between the heat switch fluid and the heat exchanger partitions.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>