How does the performance of a micro-channel heat exchanger with a condenser coil evaluate to different warmth exchanger sorts?

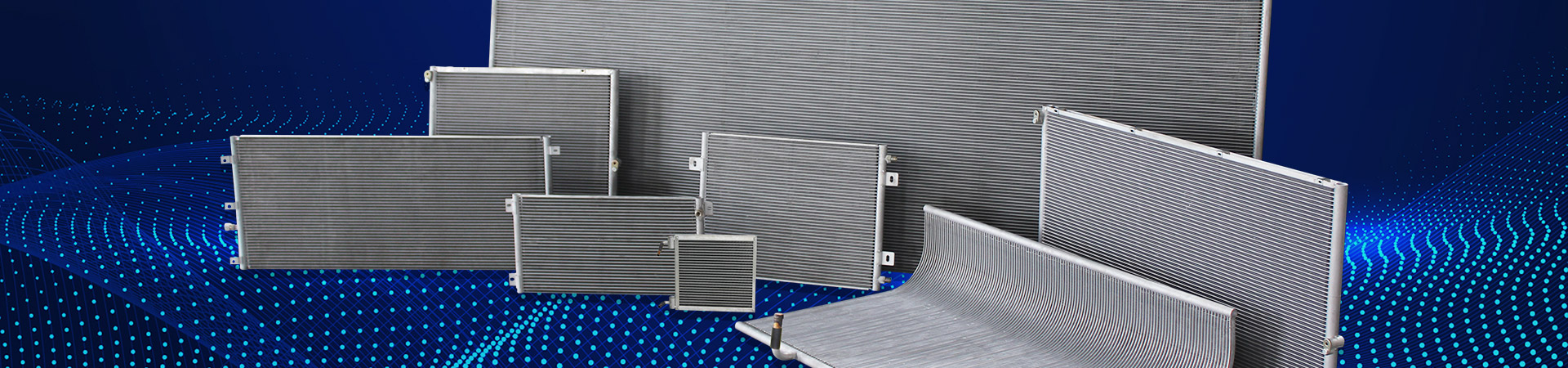

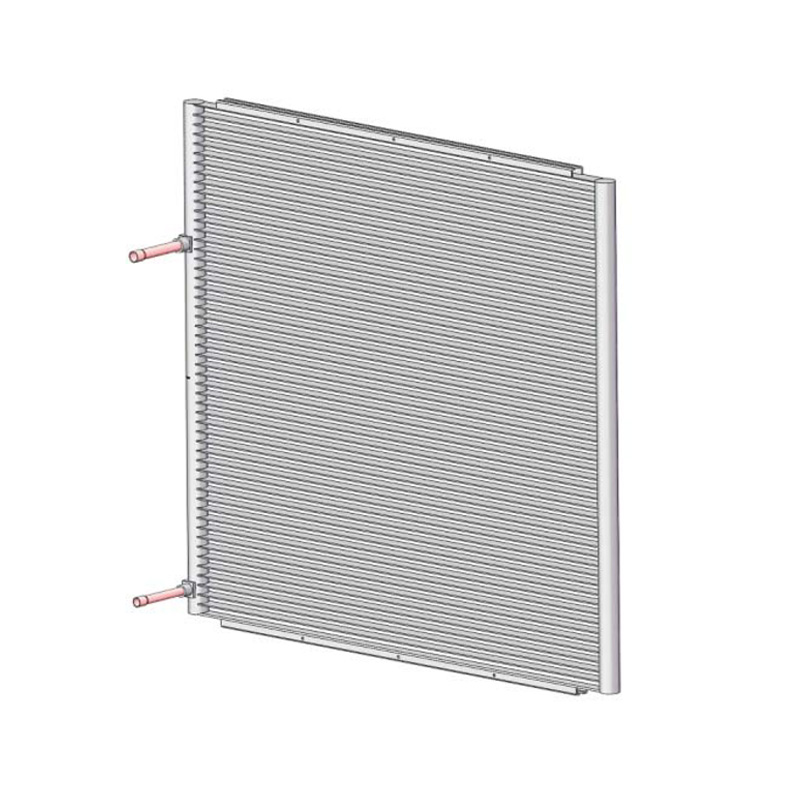

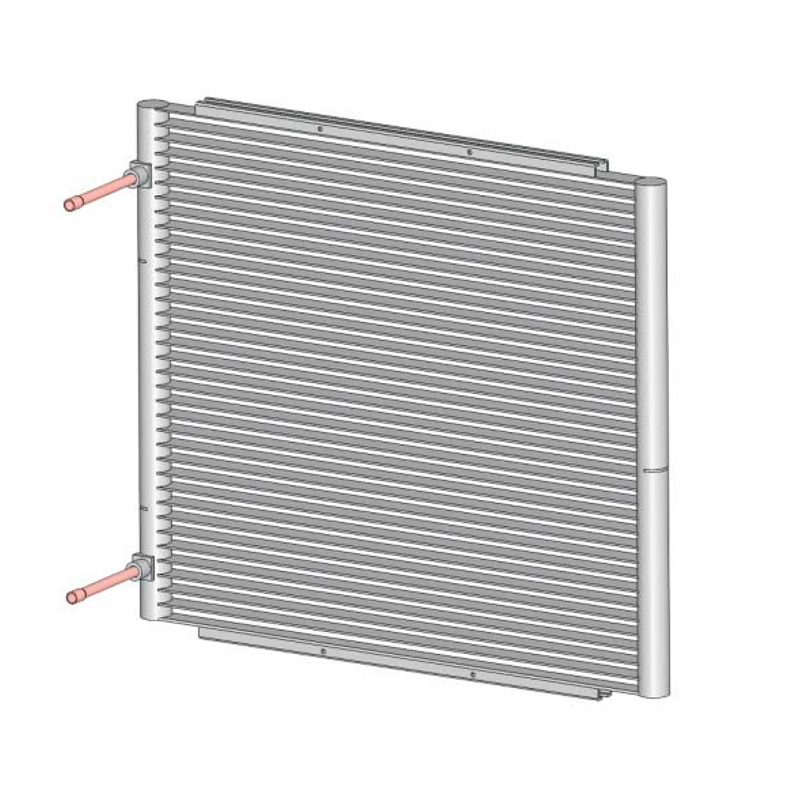

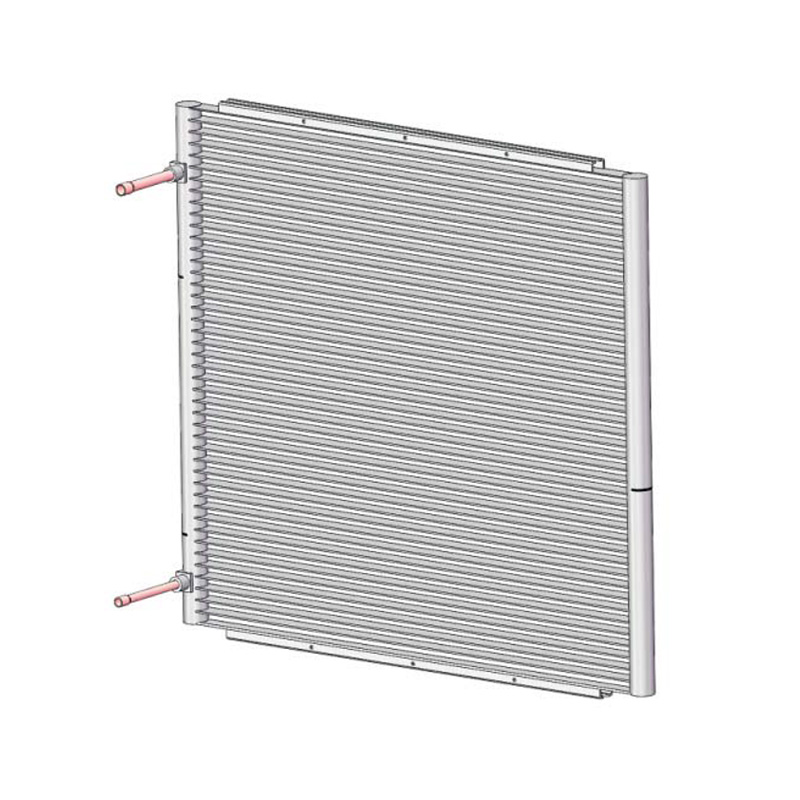

A micro-channel heat exchanger with a condenser coil is normally used in air conditioning structures, refrigeration systems, and heat pumps. It gives numerous blessings over other heat exchanger sorts, along with better efficiency, compact size, decreased refrigerant price, and lower running expenses.

The performance of a heat exchanger refers to its potential to transfer heat among two fluids even as minimizing strength losses. In this example, the micro-channel heat exchanger with a condenser coil efficaciously transfers warmth from the refrigerant to the encompassing air or water, depending at the unique utility. This heat transfer procedure is important in condensing the refrigerant vapor right into a liquid state, freeing warmth within the technique.

Compared to other styles of heat exchangers, consisting of shell and tube or plate heat exchangers, micro-channel heat exchangers provide extra performance due to their enhanced warmth transfer characteristics. The micro-channel layout features severa small channels or tubes that allow for a larger floor region-to-extent ratio. This means a better amount of heat can be transferred in step with unit volume, resulting in stepped forward warmth alternate performance.

Additionally, the micro-channel design promotes better fluid mixing and turbulence, which further complements the warmth switch charge. The turbulent drift helps in breaking down the boundary layer and reducing the thermal resistance, thereby growing the overall performance.

Another gain of micro-channel heat exchangers is their compact length. The small size allows for clean integration into diverse machine designs, making them ideal for space-limited packages. Compared to conventional heat exchangers, micro-channel heat exchangers require less space and may be organized in unique configurations, giving designers more flexibility in system layout and installation.

Furthermore, micro-channel heat exchangers offer reduced refrigerant charge. The smaller length and increased performance of the micro-channels enable a decrease in the quantity of refrigerant needed to attain the desired cooling or heating effect. This not only reduces the environmental effect but also lowers the operating costs associated with the refrigerant price.

The decreased refrigerant rate additionally minimizes the capability for refrigerant leaks and improves gadget reliability. With smaller quantities of refrigerant circulating, the risk of leakage decreases, enhancing average device performance and durability.

In phrases of warmth exchanger protection, micro-channel heat exchangers are particularly simpler to smooth and maintain in comparison to other types. The small channels permit for higher get admission to and cleaning of the inner surfaces, preventing the accumulation of contaminants, including dust, dirt, or scale which can reduce performance. Regular cleaning and maintenance help to hold most excellent heat transfer performance and extend the lifespan of the heat exchanger.

What are the important thing factors to recollect whilst selecting a condenser coil for a micro-channel heat exchanger?

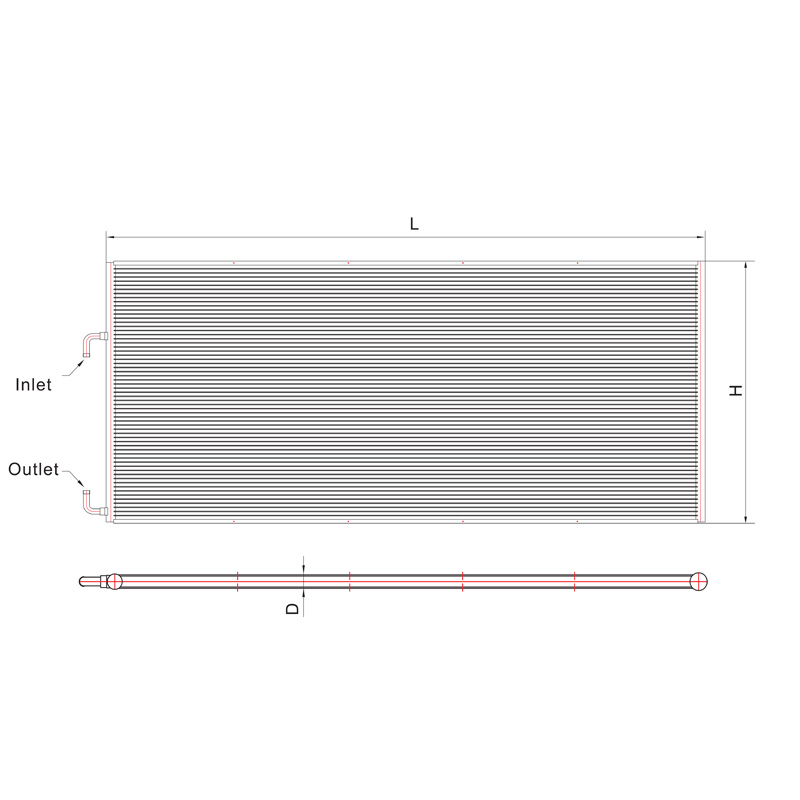

1. Heat switch ability: The number one characteristic of a condenser coil is to switch warmth from the refrigerant to the encircling air or water. Therefore, it is vital to bear in mind the heat switch capability of the coil. This may be decided by factors which include the coil's surface place, fin design, and cloth selection. A large floor area allows for elevated heat transfer, even as efficient fin layout promotes higher airflow and heat dissipation.

2. Material choice: The preference of substances for the condenser coil is critical to its overall performance and sturdiness. Copper and aluminum are usually used materials owing to their extraordinary thermal conductivity. Copper offers advanced heat switch talents but comes at a better value. Aluminum, on the other hand, is light-weight and price-powerful but has slightly lower thermal conductivity. Other elements to remember consist of corrosion resistance and compatibility with the refrigerant being used.

3. Coil configuration: The coil configuration refers to the association of tubes and fins within the condenser coil. The configuration can vary relying on the heat exchanger's utility and area constraints. Common configurations encompass flat plate, serpentine, and parallel drift. The choice of configuration should make certain most heat switch performance and easy maintenance.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>