An evaporator is a heat transfer device used to efficiently convert liquid to vapor by efficiently transferring heat energy, turning liquid into a gaseous state. Once created, the vapor may either be removed, stored for future use (like refrigeration), or separated from any impurities (for instance during distillation). Evaporators are widely used to cool air in residential and commercial buildings but also have many other applications including industrial facilities, cooling towers, refrigerators or air conditioners in households, and more.

An evaporator works by applying heat energy directly onto the surface of a liquid, which causes it to evaporate. This occurs as the temperature of liquid increases and causes molecules to move more quickly - this phenomenon is called the latent heat of vaporization - eventually breaking apart intermolecular bonds that hold them together, turning liquid into vapor and leaving behind nothing but residues of substance.

Control of this process can be challenging; an incorrectly configured evaporator could result in product loss or system failure, for instance when circulation stops due to pump failure; heat transfer surfaces in an evaporator could become covered in foam, diminishing its efficiency evaporation process; such foaming could be caused by temperature differences, viscosity differences between liquids or ingredients that have high heat sensitivity.

Product fouling is another frequent issue in food processing plants, occurring when hard deposits accumulate on the surfaces of heating mediums in an evaporator, decreasing evaporation rates and leading to poor product quality. Proteins and polysaccharides found in the foods being processed often contribute to this phenomenon.

Some evaporators are specifically designed to combat these issues. A Marangoni-flow evaporator for instance features an internal flow channel to move liquid away from the evaporation surface and towards its vapor outlet, helping reduce any chances of product fouling.

One way to solve this problem is to increase vapor outlet temperature to decrease refrigerant vapor pressure and allow the refrigerant vapor to escape at lower temperatures, thus decreasing overall energy costs associated with operating the system.

Finally, it's essential to keep in mind that an evaporator only transfers certain amounts of heat under certain circumstances. For instance, an air conditioning evaporator only transfers around 35 degrees of heat when passing over it.

Install a pump to create continuous liquid circulation in a multi-effect evaporator for efficient use of high-viscosity liquids in the dairy, pharmaceutical, and food industries. Due to its larger surface area, multi-effect evaporators can transfer more heat than their falling film counterparts.

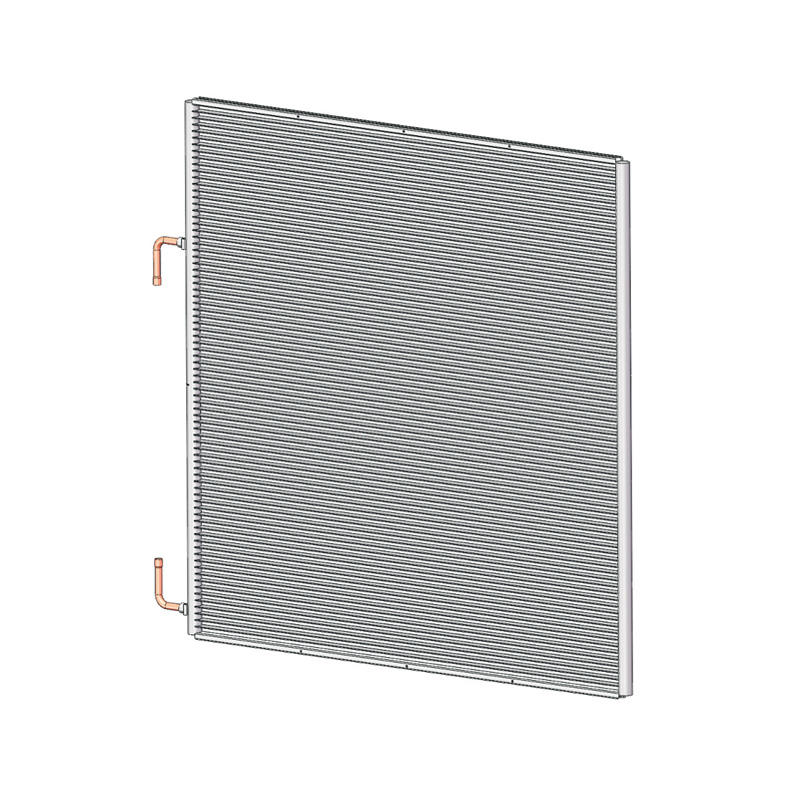

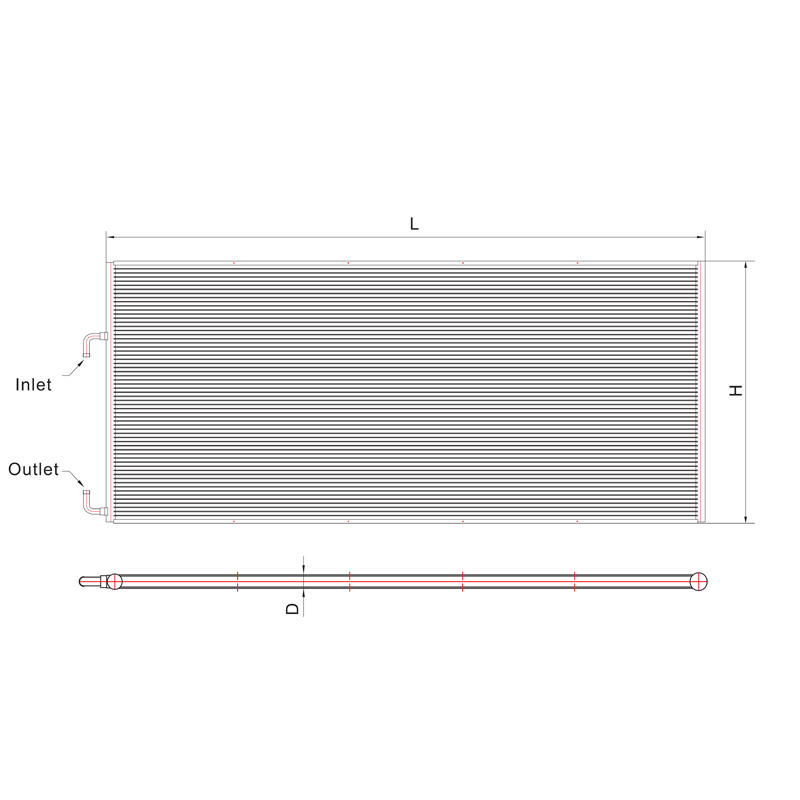

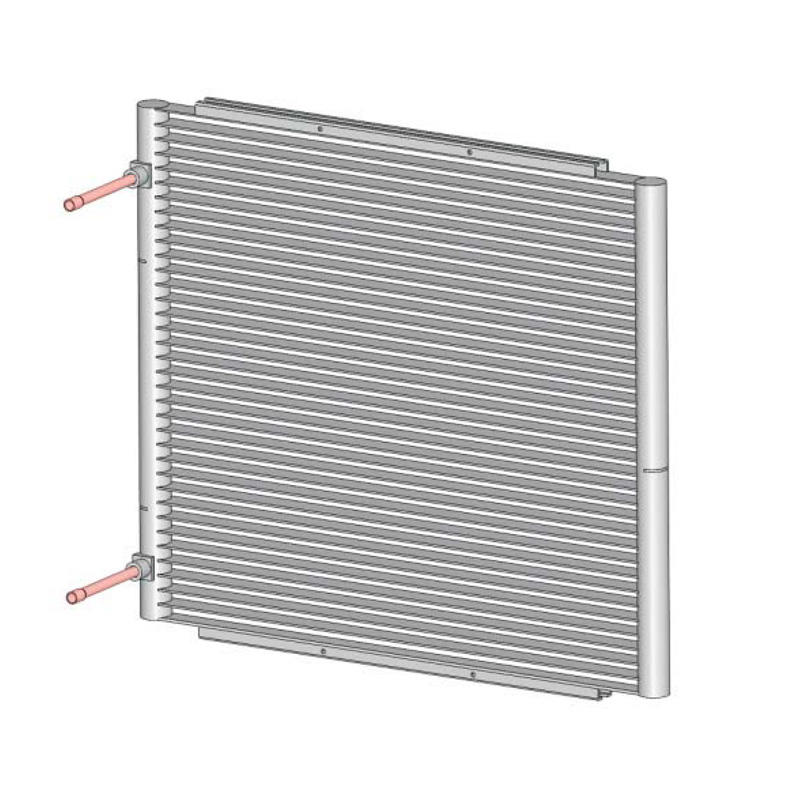

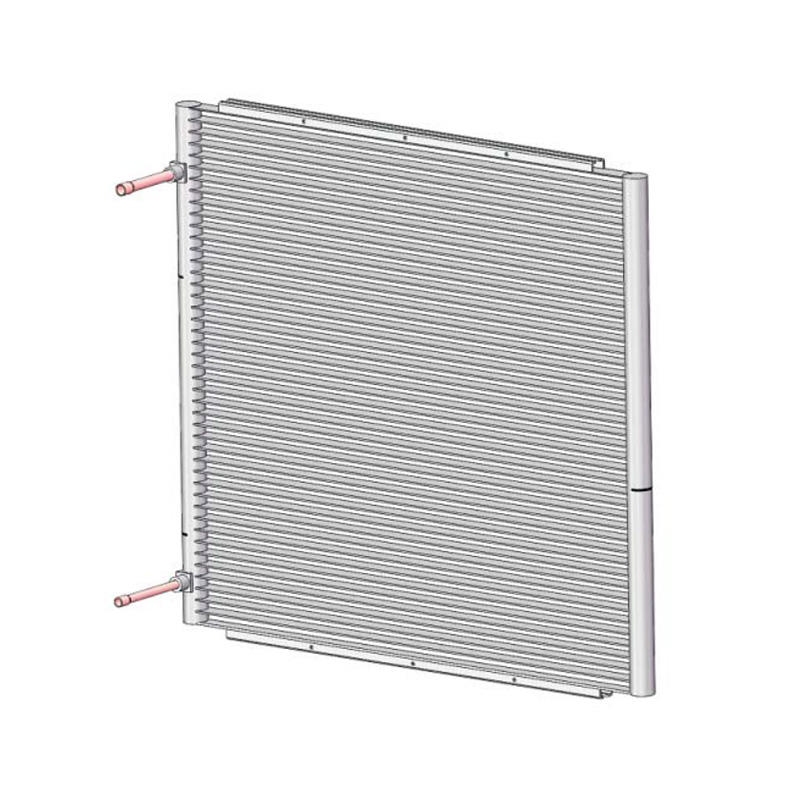

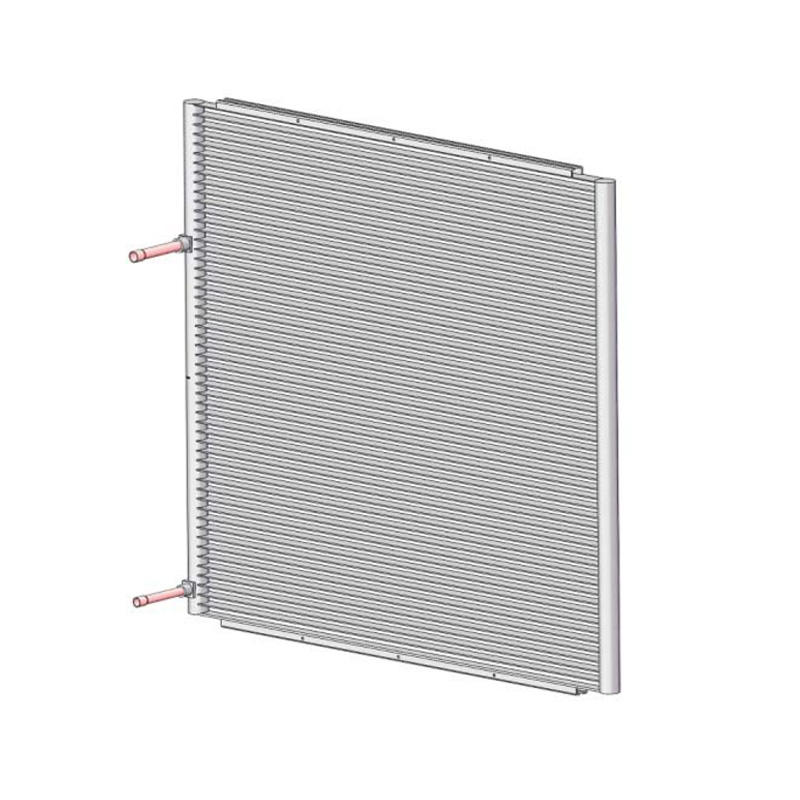

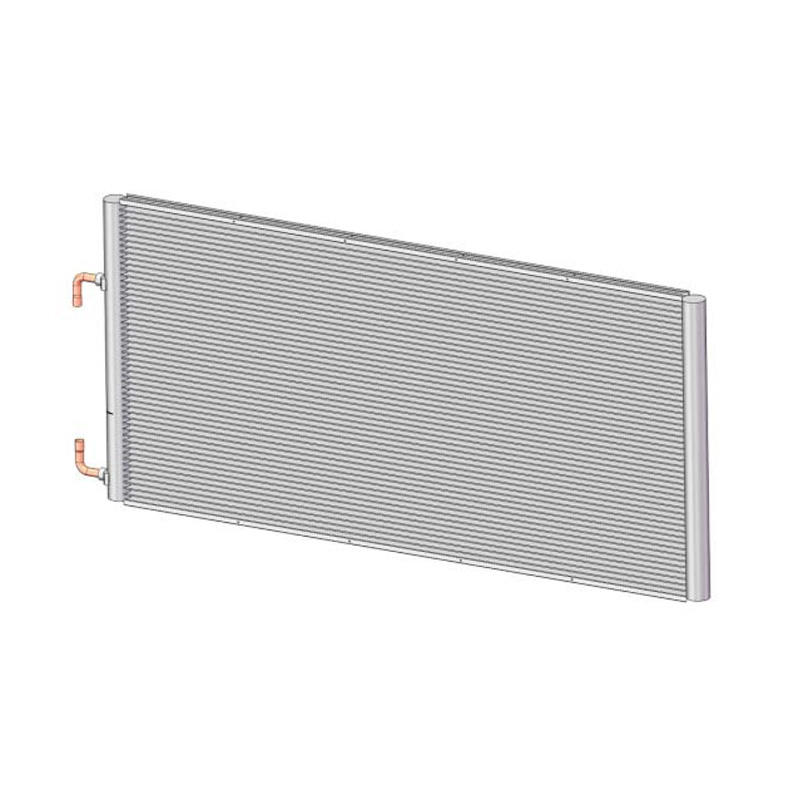

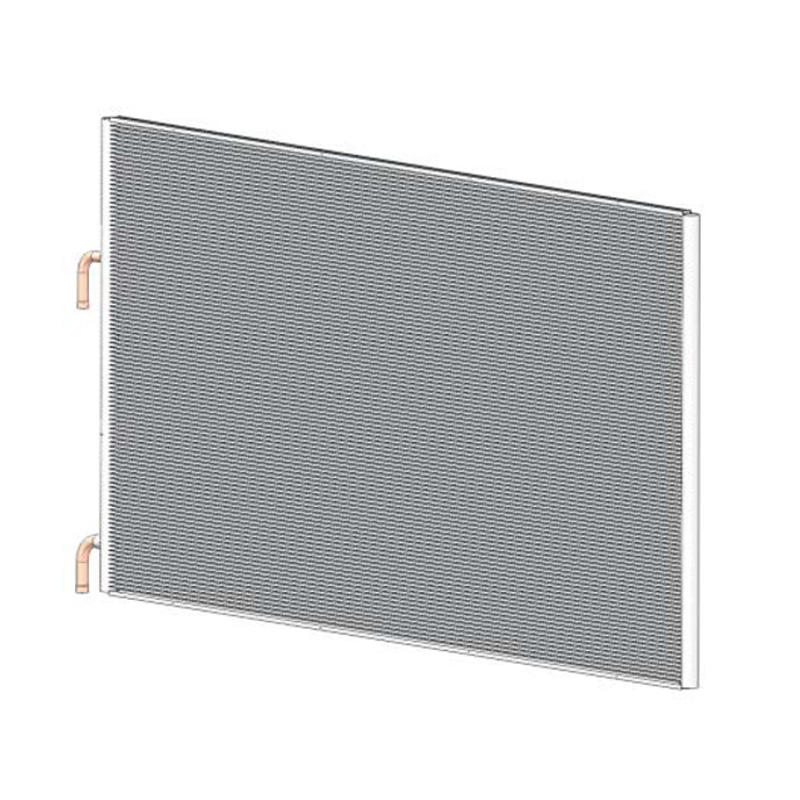

SC-1600 1280*618.5mm Micro Channel Heat Exchanger For Refrigerator Condenser Evaporator Coil

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>