In the power industry, large generator sets generate a large amount of heat when running, which requires extremely high heat dissipation equipment. Can the Copper Tube Aluminum Fin Heat Exchanger meet the efficient heat dissipation needs of the generator set and ensure stable operation of the equipment?

In the power industry, large generator sets do generate a lot of heat when running, so heat dissipation equipment is crucial to ensure the stable operation of the generator set. Regarding the question of whether the Copper Tube Aluminum Fin Heat Exchanger can meet the efficient heat dissipation needs of the generator set, we can analyze it from the following aspects:

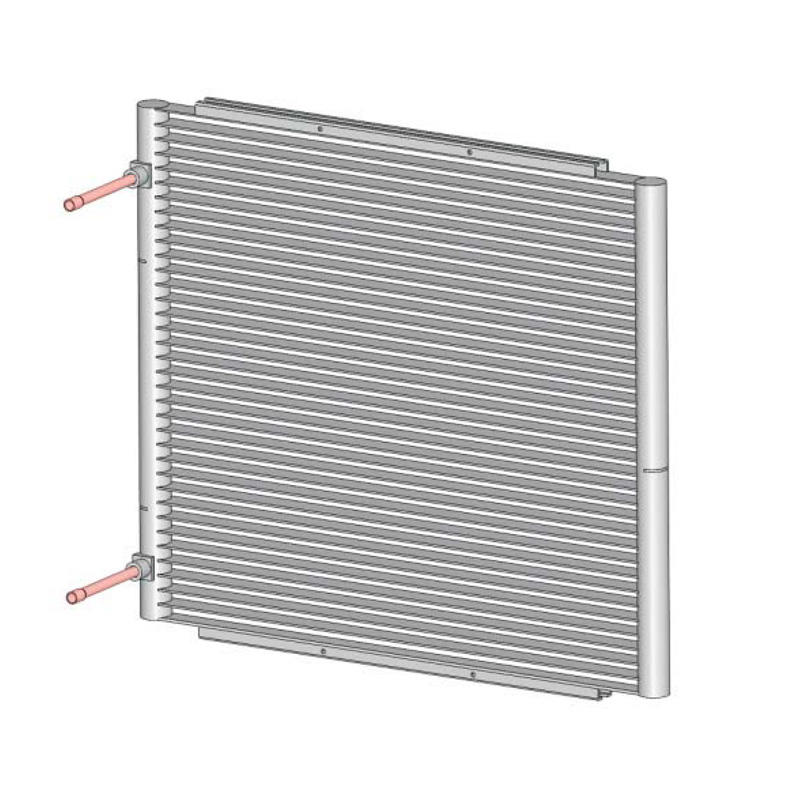

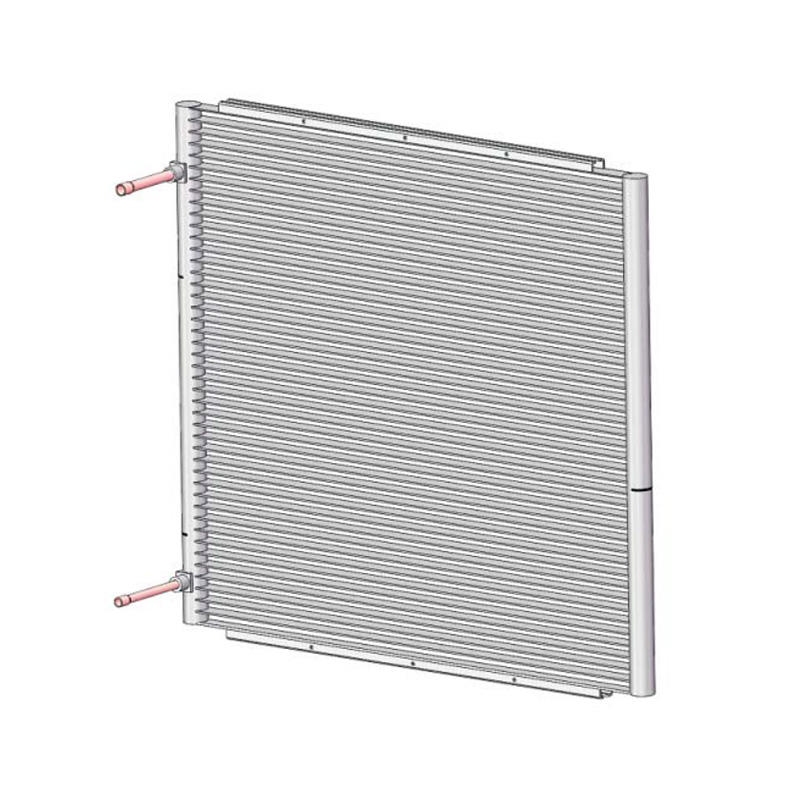

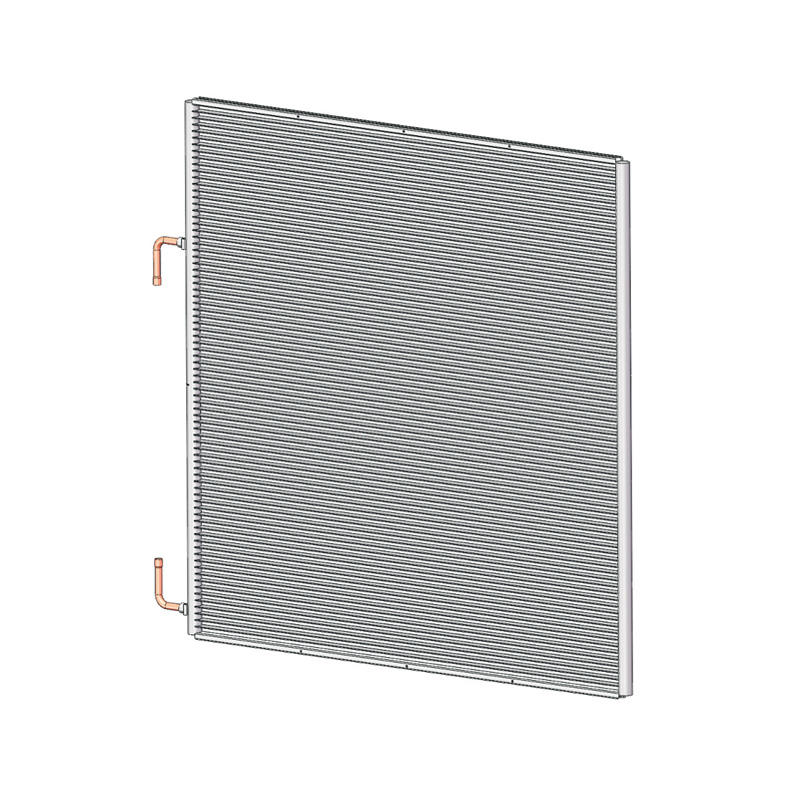

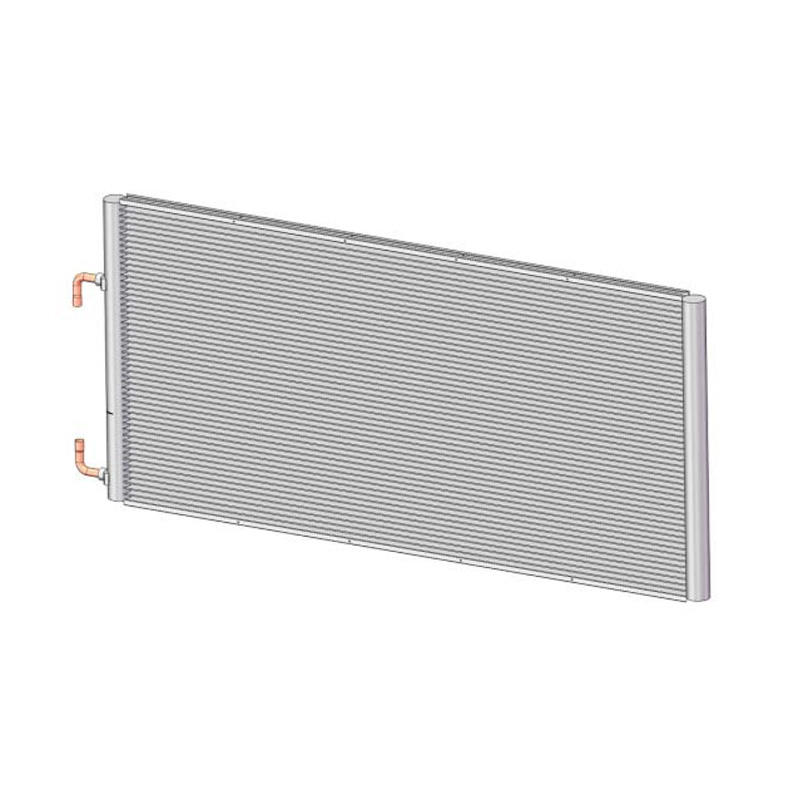

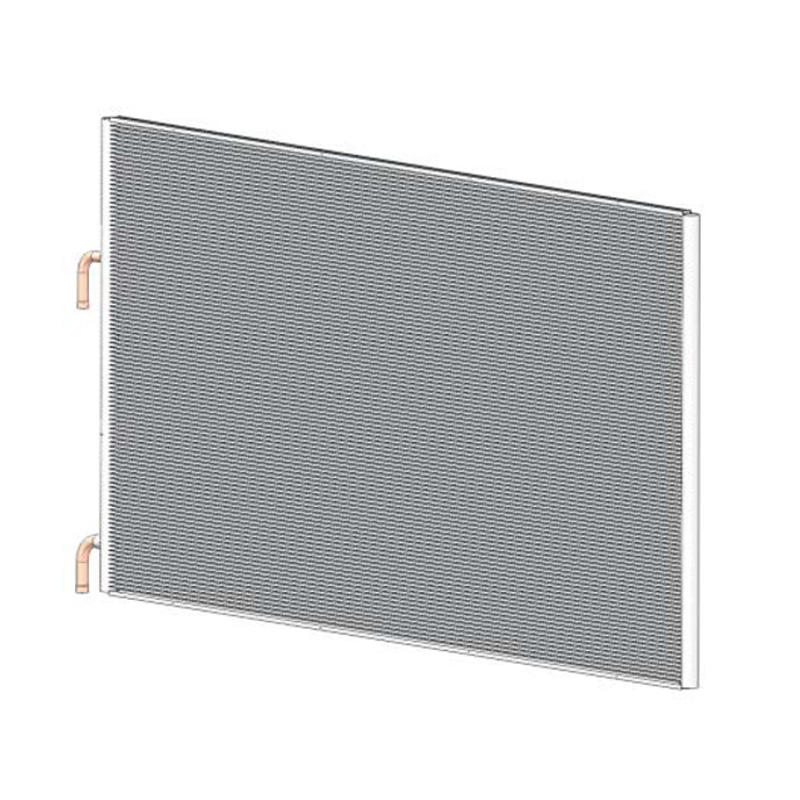

First of all, Copper Tube Aluminum Fin Heat Exchanger combines the advantages of copper tubes and aluminum fins. The copper tube has good thermal conductivity, while the aluminum fins increase the heat dissipation area. This structure enables the heat exchanger to quickly transfer the heat generated by the generator set out per unit time, thereby effectively reducing the temperature of the equipment.

Secondly, the design of aluminum fins not only increases the heat dissipation area, but also improves heat dissipation efficiency. Aluminum fins can quickly disperse heat to a larger surface and take away heat through air convection, thus ensuring that the generator set does not generate excessive temperatures during operation.

In addition, Copper Tube Aluminum Fin Heat Exchanger has high corrosion resistance and reliability. The working environment in the power industry is usually complex, and there are many factors that may cause corrosion to the radiator. The copper tubes and aluminum fins of this heat exchanger have certain corrosion resistance and can operate stably for a long time in harsh environments.

Finally, in order to meet the efficient heat dissipation needs of the generator set, the Copper Tube Aluminum Fin Heat Exchanger also needs to be properly laid out and installed. By optimizing the number and location of radiators, and rationally designing the pipes and air ducts of the cooling system, the heat dissipation efficiency can be further improved and the stable operation of the generator set can be ensured.

With its excellent thermal conductivity, heat dissipation efficiency and corrosion resistance, Copper Tube Aluminum Fin Heat Exchanger can meet the efficient heat dissipation needs of large generator sets in the power industry and ensure the stable operation of the equipment. However, in actual applications, reasonable design, layout and installation are required according to specific conditions to achieve the best heat dissipation effect.

Round Shape Multiple Bending Microchannel Condenser Coils For Auto/Caravan Air Conditioner

Round Shape Multiple Bending Microchannel Condenser Coils For Auto/Caravan Air Conditioner

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>