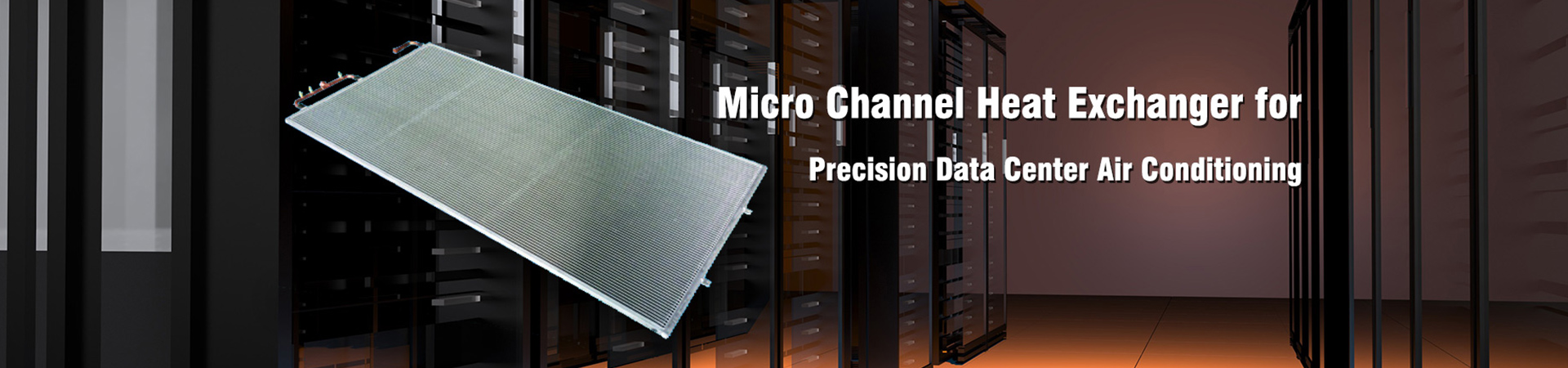

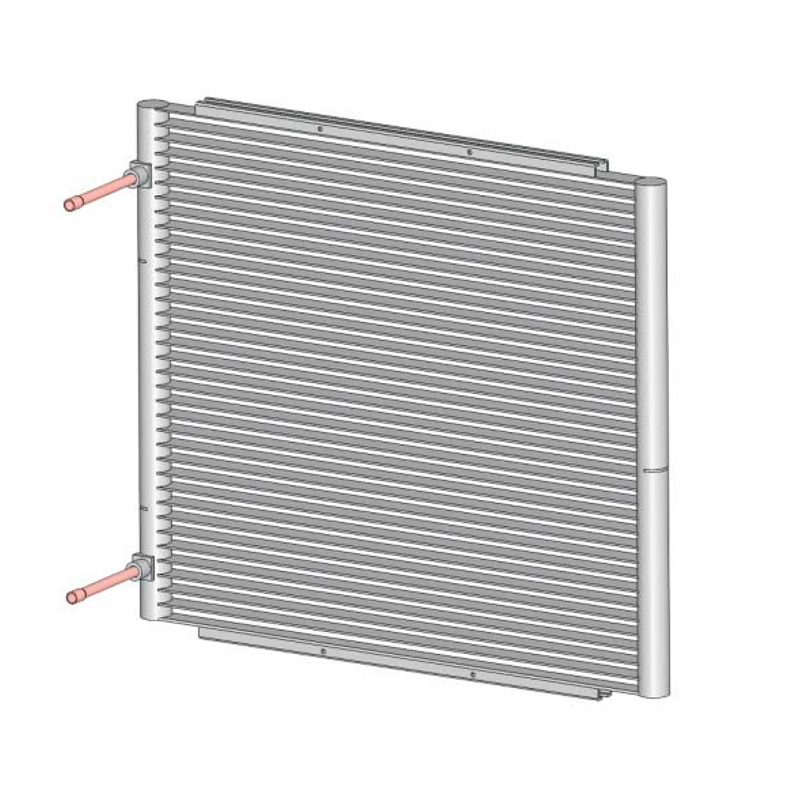

Micro Channel Heat Exchangers (MCHEs) are advanced thermal management devices widely used in industries requiring high heat transfer efficiency in a compact form factor. Unlike traditional fin-and-tube heat exchangers, MCHEs utilize flat tubes with small hydraulic diameters and integrated microchannels, enhancing heat exchange while reducing weight and refrigerant charge. Their superior thermal performance, corrosion resistance, and lightweight design make them ideal for applications in HVAC&R, automotive, aerospace, and electronics cooling.

1. Micro Channel Heat Exchanger Applications in HVAC

Micro Channel Heat Exchangers (MCHEs) have revolutionized the HVAC (Heating, Ventilation, and Air Conditioning) industry by offering improved energy efficiency, reduced refrigerant usage, and space-saving designs.

Key HVAC Applications of MCHEs:

Residential & Commercial Air Conditioning: MCHEs are widely used in modern split and packaged AC units due to their compact size and high heat transfer rates.

Heat Pumps: Their ability to handle both heating and cooling modes efficiently makes them ideal for heat pump systems.

Refrigeration Systems: MCHEs improve cooling performance in supermarket display cases, cold storage, and transport refrigeration.

Data Center Cooling: Their high thermal efficiency supports liquid cooling solutions for high-density server racks.

Advantages in HVAC Systems:

Higher Energy Efficiency – Reduced thermal resistance improves COP (Coefficient of Performance).

Lower Refrigerant Charge – Smaller internal volume minimizes environmental impact.

Compact & Lightweight – Easier installation and reduced material costs.

Corrosion Resistance – Aluminum-based MCHEs resist degradation in harsh environments.

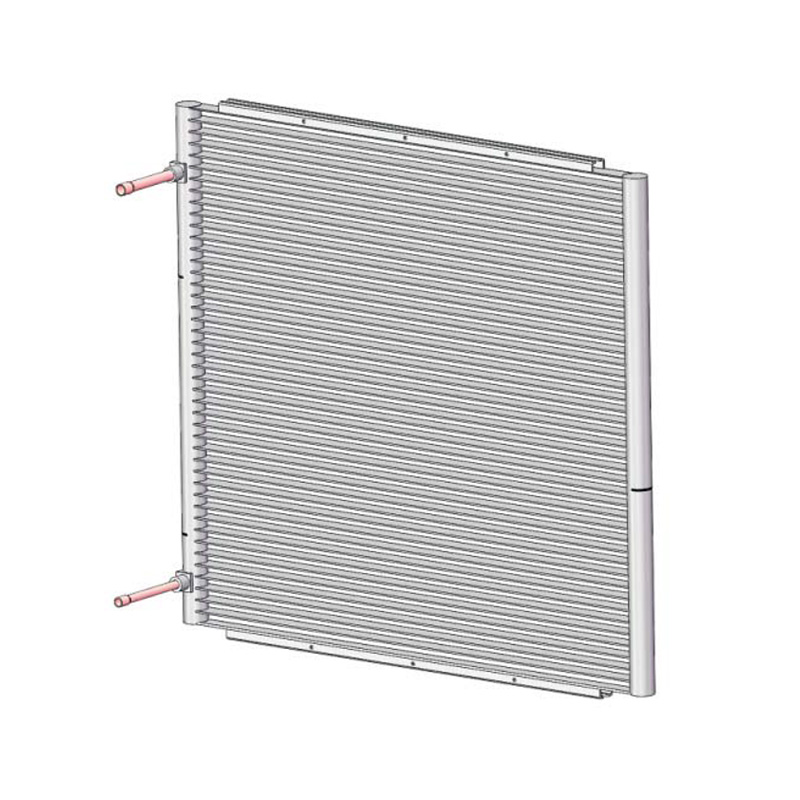

SC-1100 388*346.7mm Car Air Conditioner MCHE Condenser Coil Microchannel Heat Exchanger

2. Micro Channel Heat Exchanger Efficiency Optimization

To maximize the performance of MCHEs, engineers focus on design improvements, material selection, and operational enhancements.

Key Optimization Strategies:

Enhanced Microchannel Geometry: Optimizing tube width, fin density, and port design to improve flow distribution and reduce pressure drop.

Advanced Materials: Using aluminum alloys with anti-corrosion coatings to extend lifespan in humid or corrosive environments.

Refrigerant Flow Management: Improving distributor designs to ensure uniform refrigerant flow across all channels.

Surface Treatments: Hydrophilic or hydrophobic coatings to enhance condensation or frost resistance.

Computational Fluid Dynamics (CFD) Analysis: Simulating airflow and refrigerant behavior to refine heat exchanger designs.

Benefits of Optimized MCHEs:

Higher Heat Transfer Rates – Improved thermal conductivity and flow dynamics.

Lower Energy Consumption – Reduced fan and compressor workload.

Longer Lifespan – Better corrosion and fouling resistance.

Cost-Effective Manufacturing – Optimized designs reduce material waste.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>