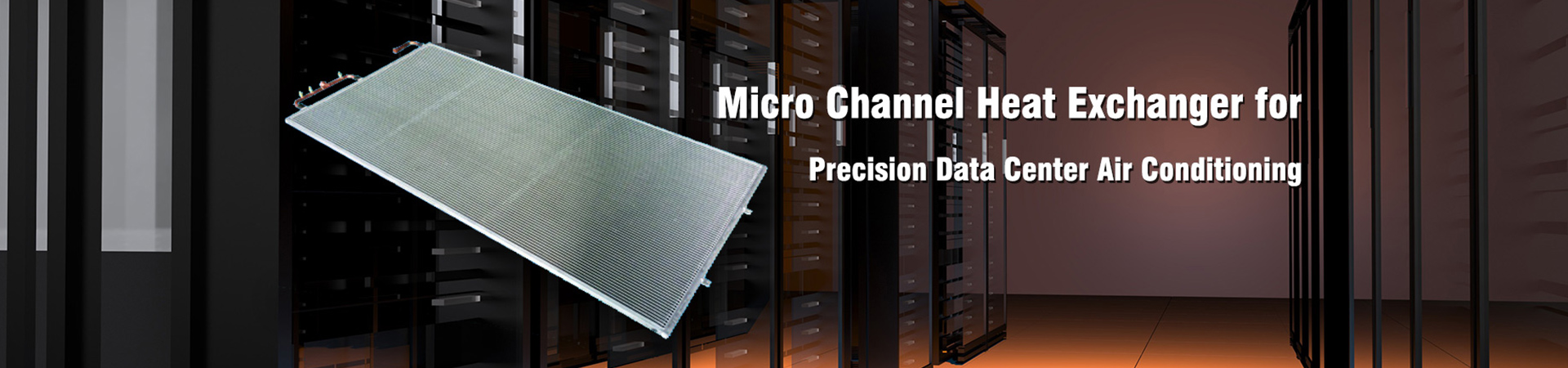

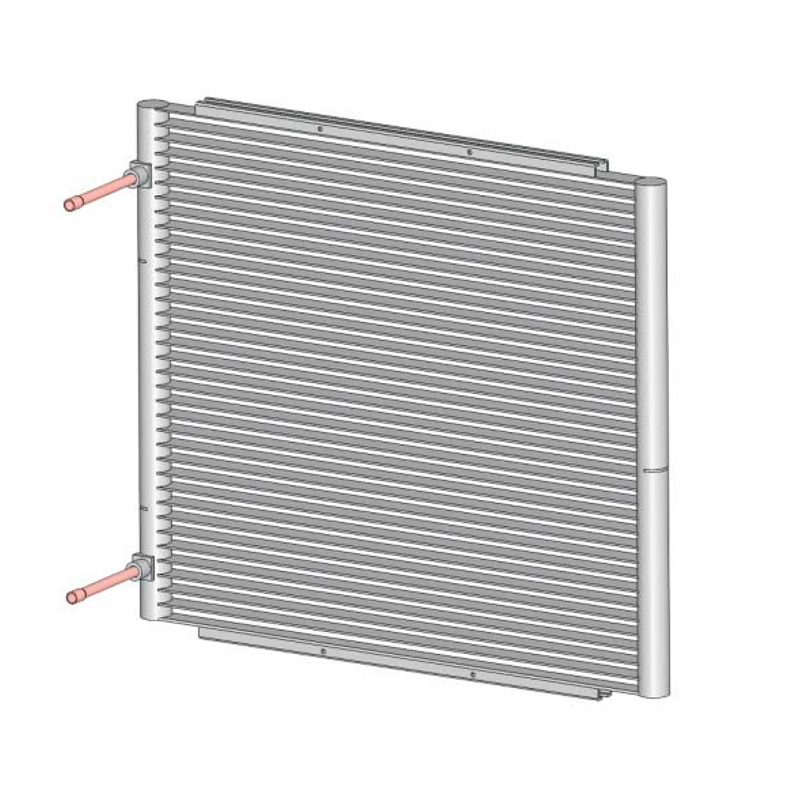

Micro-Channel Heat Exchanger Condenser Coil For Refrigerator & Standard Range Applications

Micro-channel heat exchangers (MCHEs) have revolutionized thermal management in automotive and refrigeration systems due to their compact design, superior heat transfer efficiency, and reduced refrigerant charge requirements.

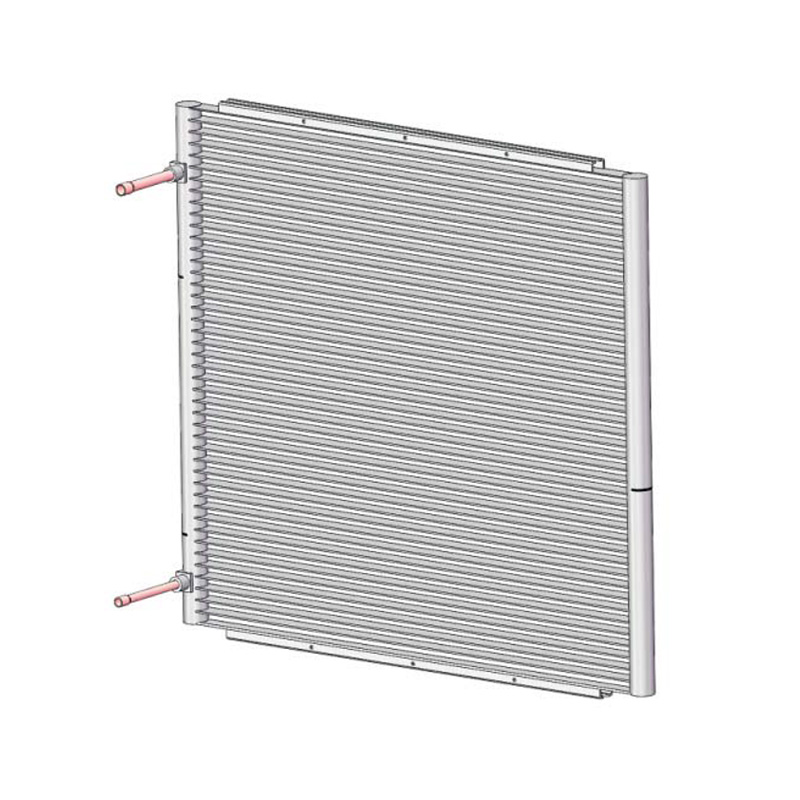

SC-1100 388*346.7mm Car Air Conditioner MCHE Condenser Coil Microchannel Heat Exchanger

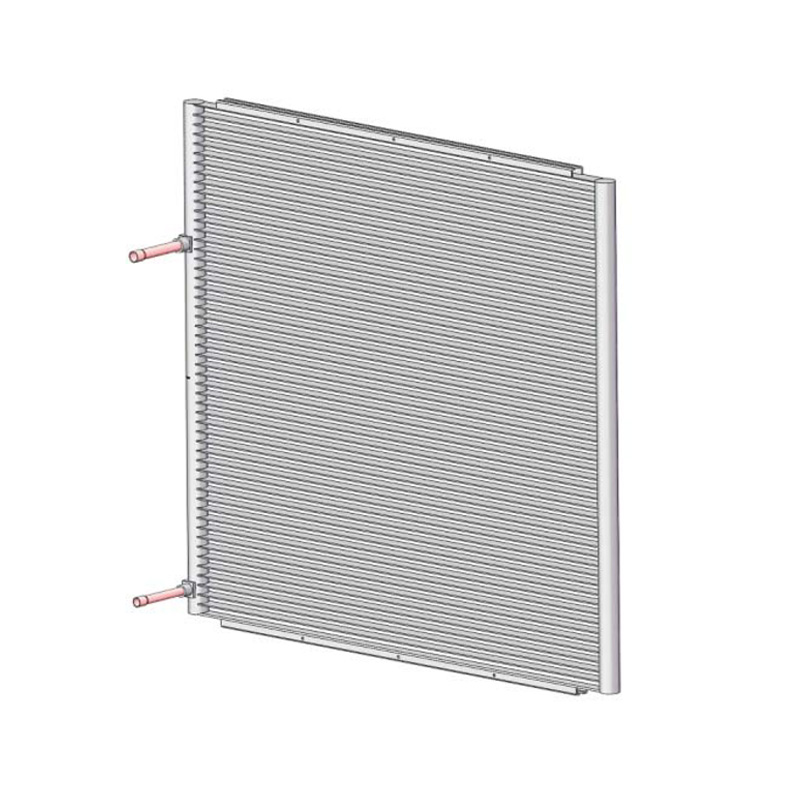

1. Car Air Conditioner MCHE Condenser Coil

Key Features & Benefits

Compact & Lightweight: Ideal for automotive applications where space and weight are critical.

Enhanced Heat Transfer: Micro-channel tubes provide higher efficiency compared to traditional fin-and-tube designs.

Lower Refrigerant Charge: Reduces environmental impact and system cost.

Corrosion Resistance: Aluminum construction ensures durability in harsh conditions.

Typical Parameters

| Parameter | Value |

|---|---|

| Material | Aluminum |

| Tube Width | 16-24 mm |

| Fin Pitch | 1.2-2.5 mm |

| Max Pressure | 35-45 bar |

| Refrigerant Compatibility | R134a, R1234yf |

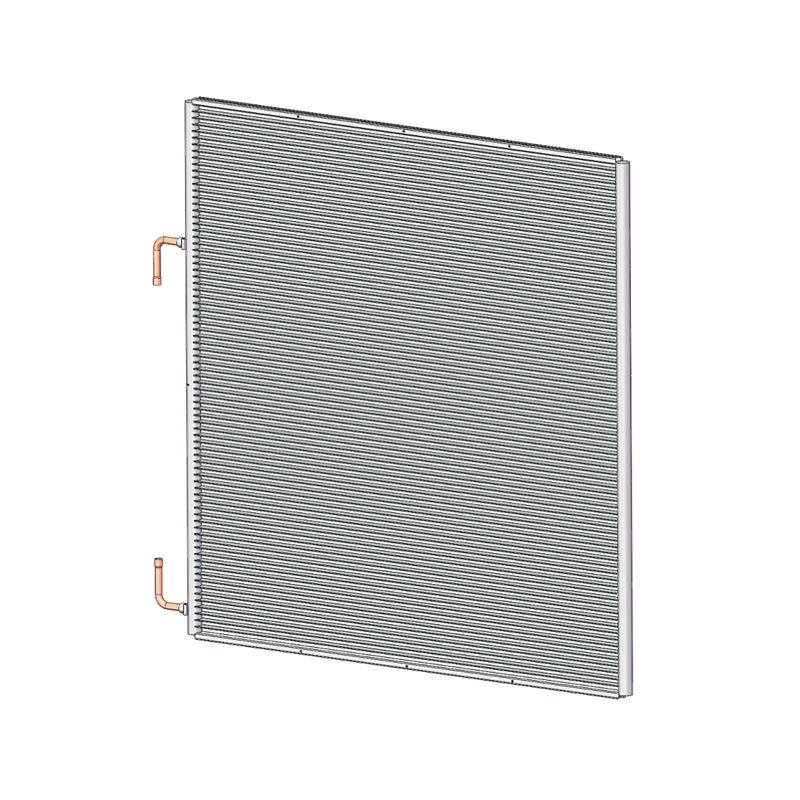

2. Micro-Channel Heat Exchanger Condenser Coil for Refrigerator

Key Features & Benefits

Energy Efficiency: Optimized for household/commercial refrigeration.

Space-Saving Design: Fits compact refrigeration units without compromising performance.

Low Frost Accumulation: Improves defrost cycles and operational efficiency.

Parameters Comparison (Car AC vs. Refrigerator MCHE)

| Parameter | Car AC MCHE | Refrigerator MCHE |

|---|---|---|

| Material | Aluminum | Aluminum/Copper |

| Operating Pressure | 35-45 bar | 15-25 bar |

| Fin Density | Higher | Moderate |

| Refrigerant Type | R134a/R1234yf | R600a/R290 |

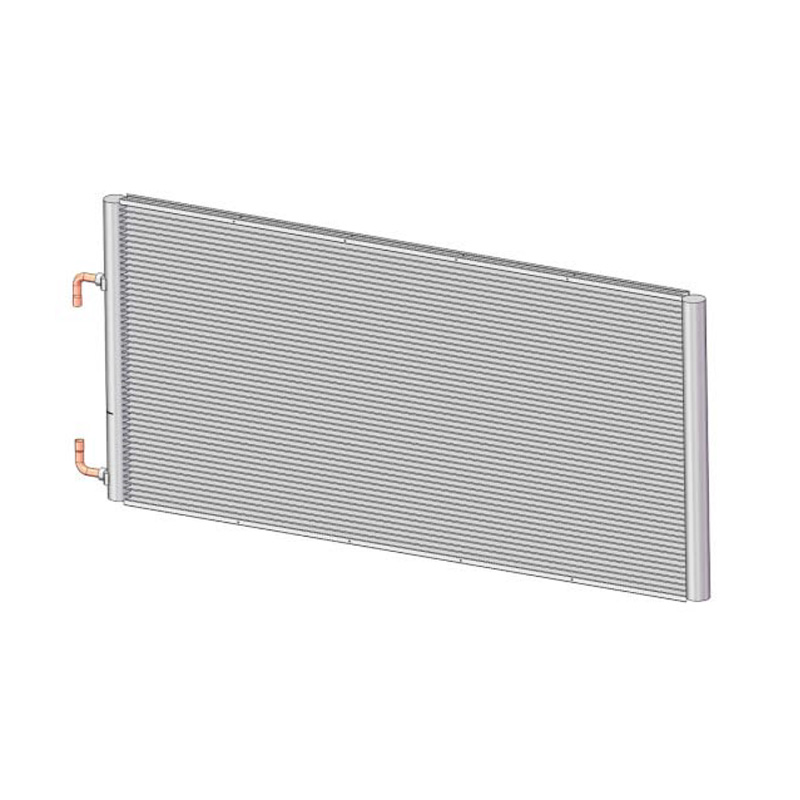

3. Standard Range Micro-Channel Heat Exchangers

Applications & Variations

Used in automotive, HVAC, and refrigeration industries.

Customizable in size, tube arrangement, and refrigerant compatibility.

Advantages Over Traditional Heat Exchangers

30-50% higher heat transfer efficiency

20-40% lighter weight

Reduced refrigerant usage by 30%

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>