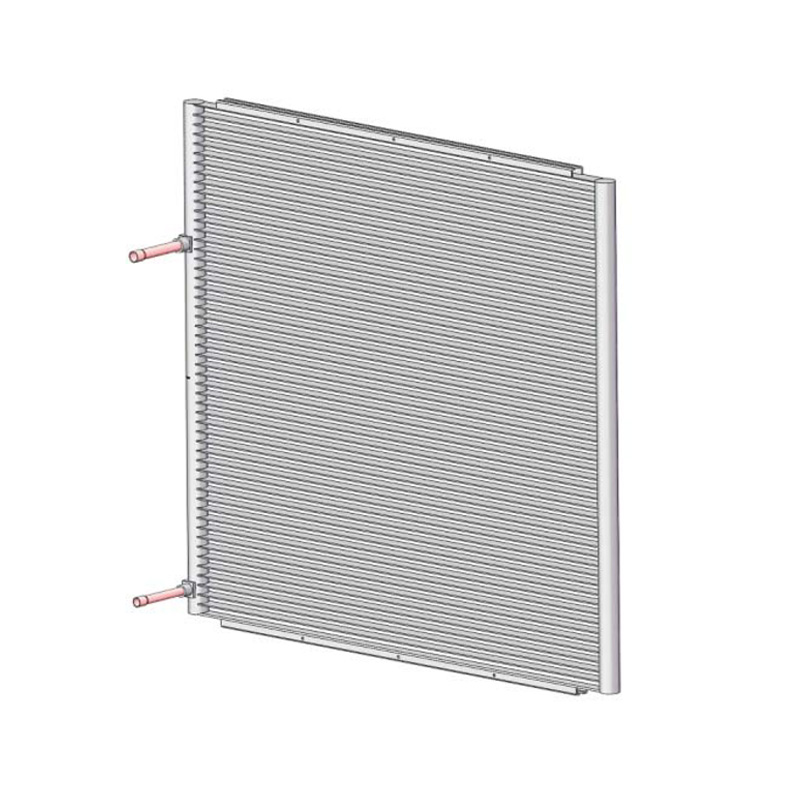

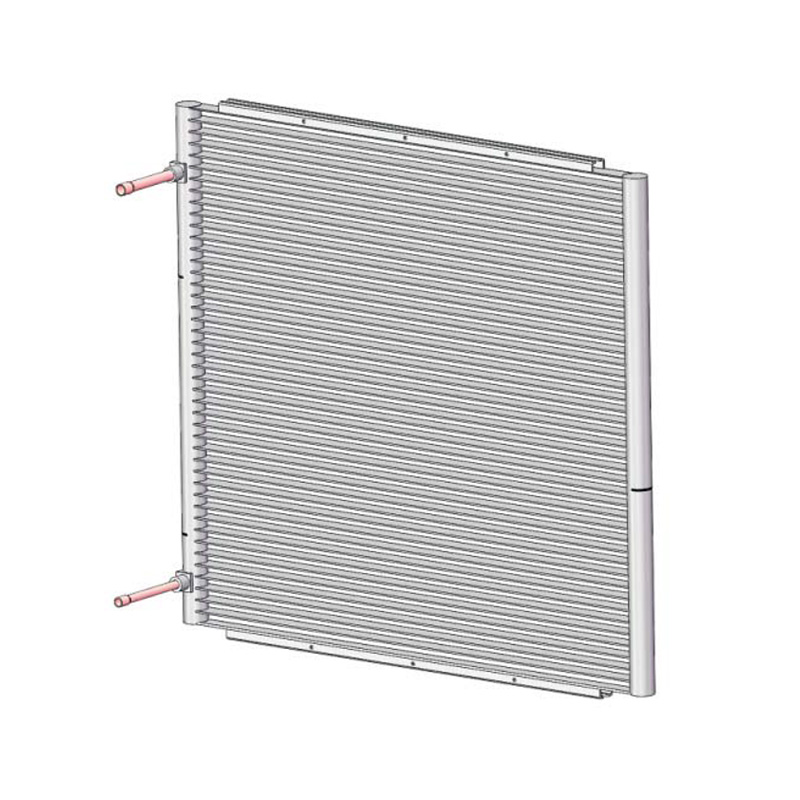

The microchannel evaporator coil represents a significant advancement in heat exchanger technology, offering improved efficiency, compact design, and enhanced thermal performance compared to traditional fin-and-tube coils.

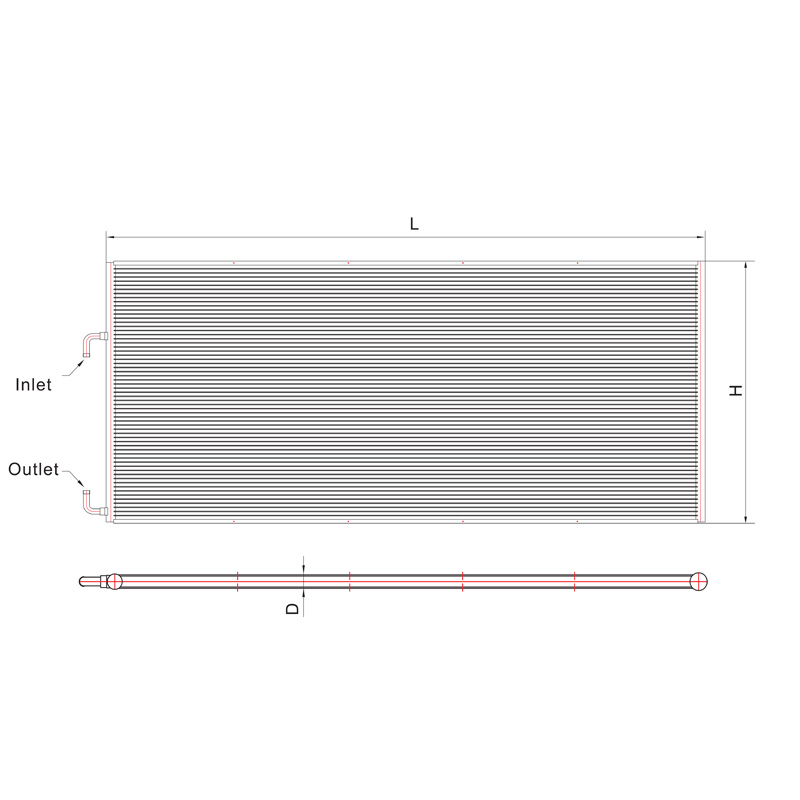

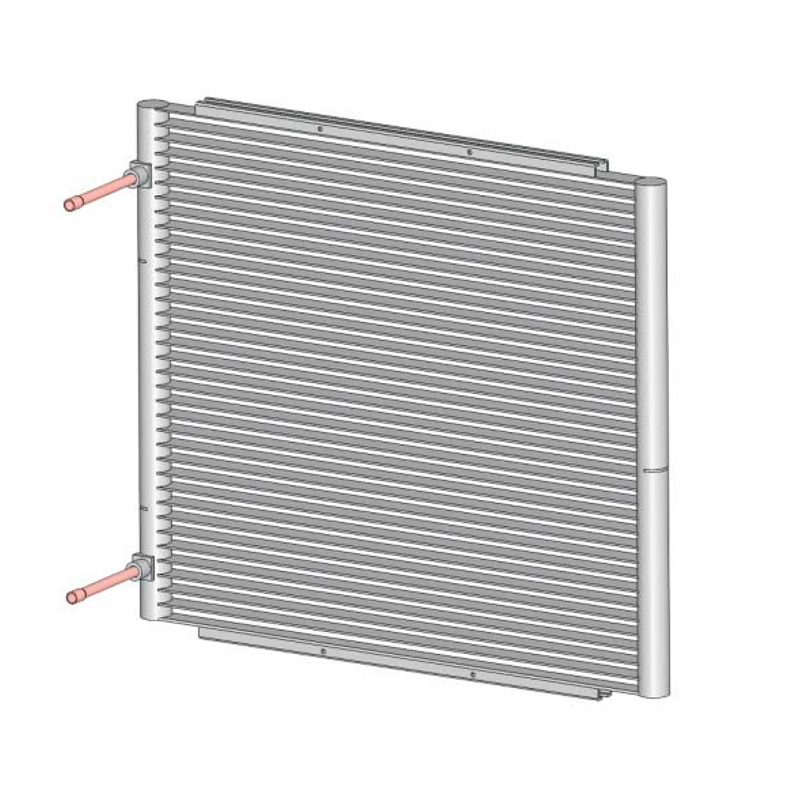

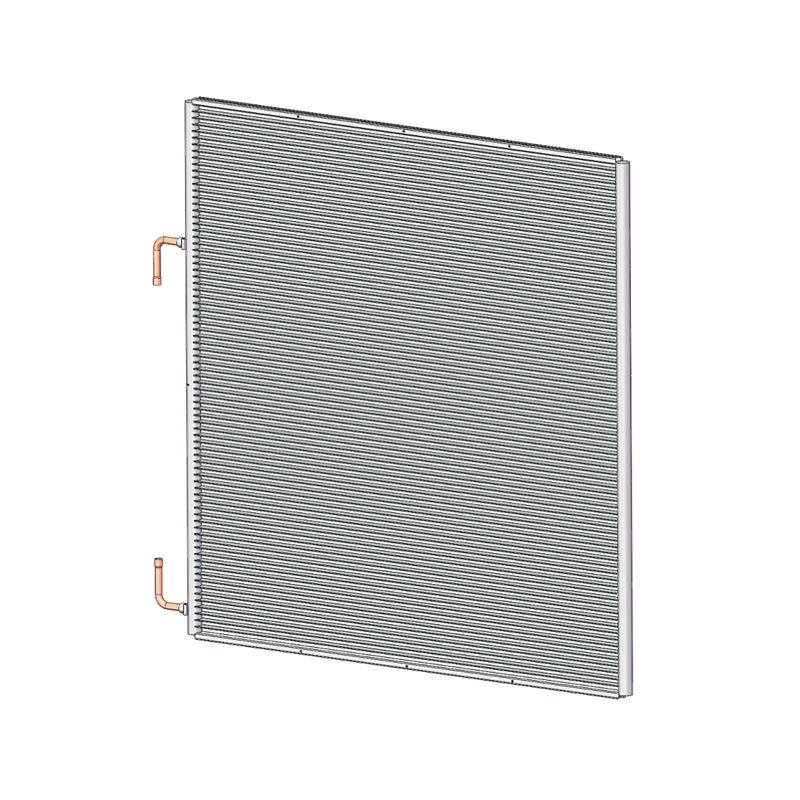

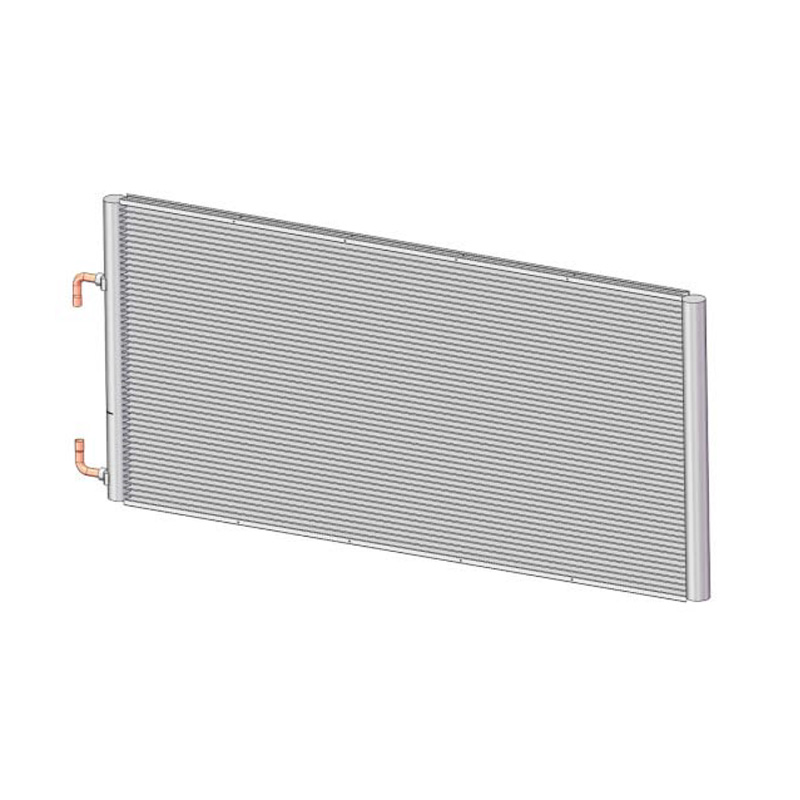

SC-1300 550*515.9mm Car/HVAC Microchannel Condenser Coil Micro Channel Heat Exchanger

Channel in Heat Exchanger: The Core of Efficient Thermal Transfer

Heat exchangers rely on carefully designed channels to facilitate the transfer of thermal energy between fluids. In a microchannel evaporator coil, these channels are significantly smaller (typically 0.5–2 mm in hydraulic diameter) than those in conventional heat exchangers, leading to several advantages:

Higher Surface Area-to-Volume Ratio: Microchannels increase heat transfer efficiency by maximizing contact between refrigerant and air.

Reduced Refrigerant Charge: Requires up to 30–50% less refrigerant compared to traditional coils, lowering environmental impact.

Improved Heat Transfer Coefficient: Microchannels enhance turbulence, boosting thermal exchange rates by 15–30%.

Data Comparison: Microchannel vs. Fin-and-Tube Coils

| Feature | Microchannel Coil | Traditional Fin-and-Tube Coil |

|---|---|---|

| Heat Transfer Efficiency | 15–30% Higher | Baseline |

| Refrigerant Charge | 30–50% Less | Higher |

| Airside Pressure Drop | Lower | Higher |

| Weight | Up to 40% Lighter | Heavier |

| Corrosion Resistance | Better (All-Aluminum) | Variable (Copper/Aluminum) |

HVAC Microchannel Coils: The Future of Cooling Systems

The HVAC industry is increasingly adopting microchannel coils due to their superior performance in evaporators and condensers. Key benefits include:

1. Energy Efficiency

Microchannel coils contribute to higher SEER (Seasonal Energy Efficiency Ratio) ratings in HVAC systems, improving overall energy savings.

Studies show 5–10% better efficiency in systems using microchannel technology.

2. Compact and Lightweight Design

Their reduced size allows for more flexible installation in tight spaces, such as rooftop units and compact air handlers.

Weight savings of 30–40% reduce shipping and handling costs.

3. Durability and Sustainability

Constructed from all-aluminum, microchannel coils resist corrosion better than copper-aluminum fin-and-tube designs.

Lower refrigerant usage aligns with environmental regulations (e.g., EPA & F-Gas directives).

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>