Comparing Copper Tube Aluminum Fin and Aluminum Tube Aluminum Fin Heat Exchangers

Heat exchangers are critical components in HVAC, refrigeration, and automotive cooling systems. Among the various types, Micro Channel Heat Exchangers (MCHEs) have gained prominence due to their compact design, superior heat transfer efficiency, and reduced refrigerant charge requirements.

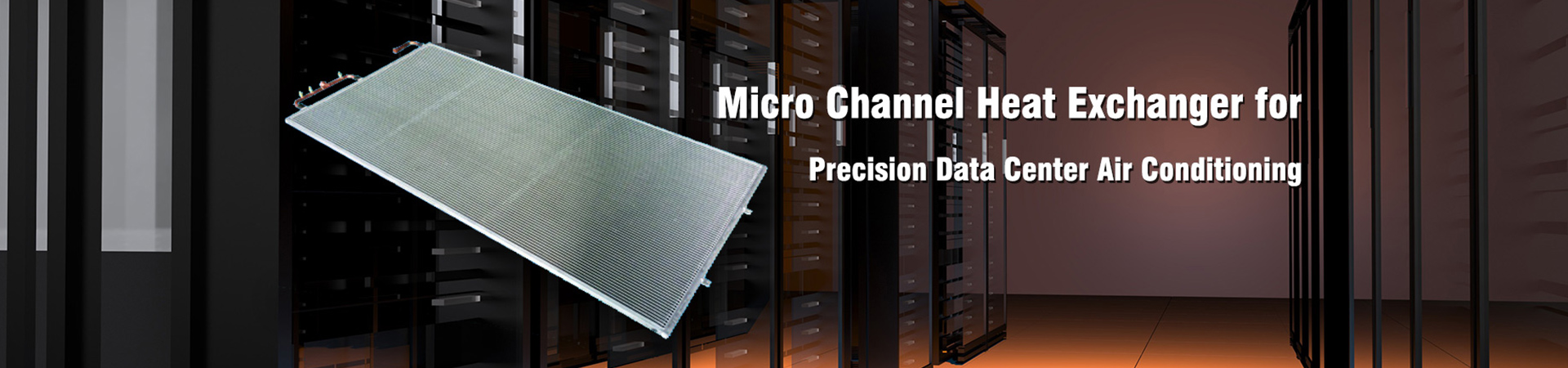

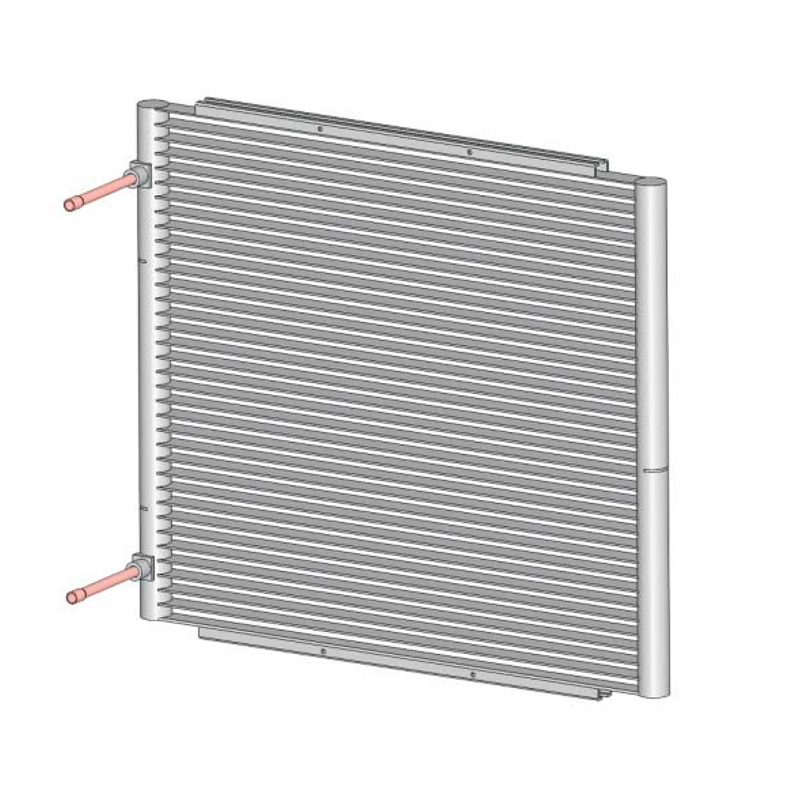

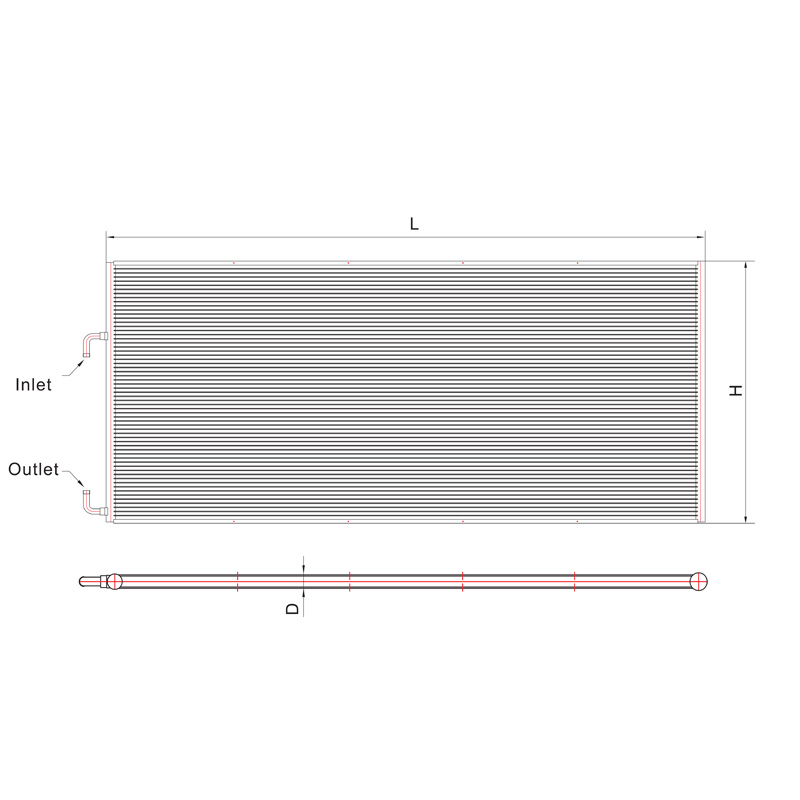

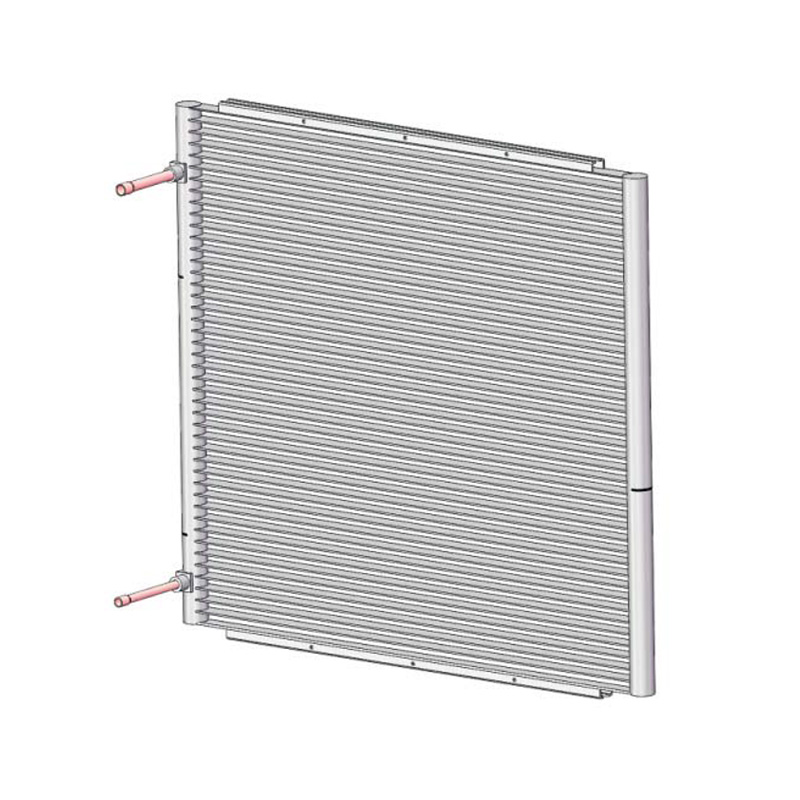

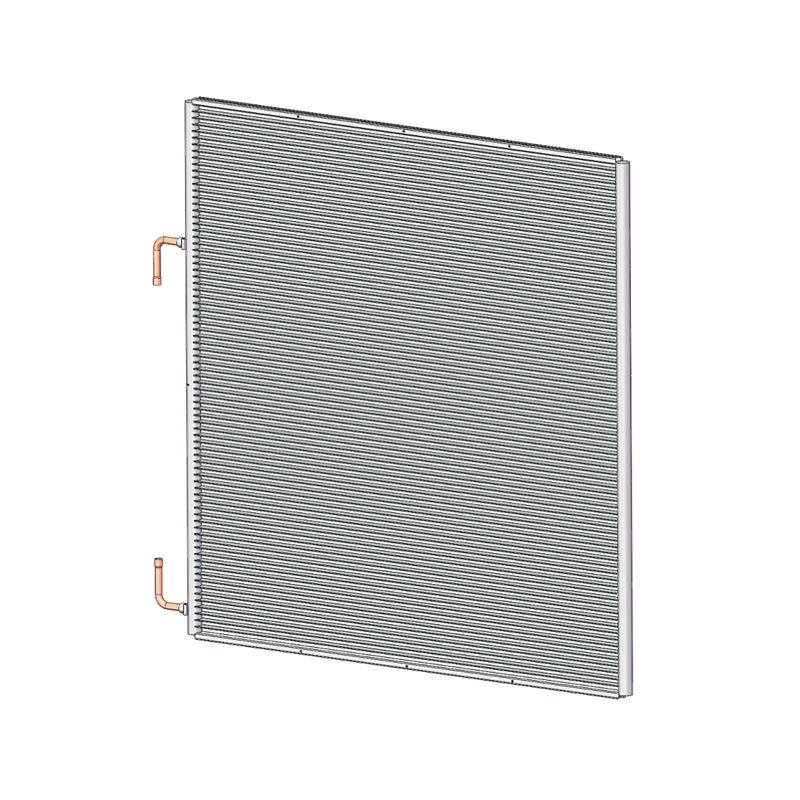

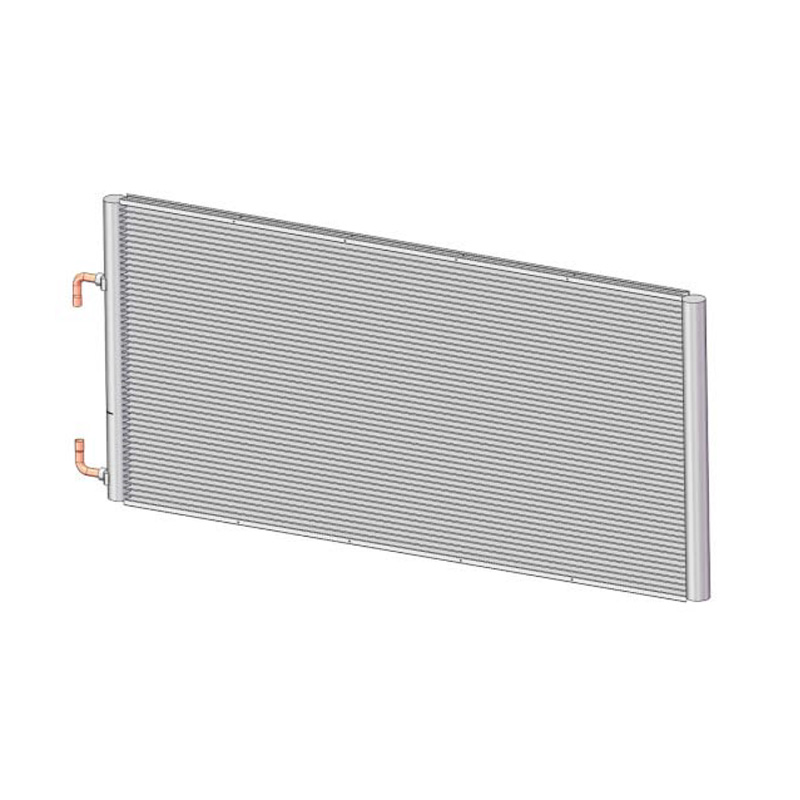

SC-1800 1074*1208mm Micro-channel Tube Heat Exchanger Condenser Evaporator Coil MCHE

What is a Micro Channel Heat Exchanger (MCHE)?

MCHEs consist of flat, multi-port aluminum tubes with integrated microchannels, paired with aluminum fins. Their design maximizes heat transfer while minimizing weight and refrigerant volume. Key benefits include:

Higher Efficiency: Microchannels increase surface area, improving heat exchange.

Lightweight Construction: Aluminum reduces weight compared to copper-based designs.

Lower Refrigerant Charge: Reduced internal volume enhances environmental compliance.

Compact Size: Ideal for applications with space constraints.

Comparison with Traditional Heat Exchangers

1. Copper Tube Aluminum Fin (CTAF) Heat Exchanger

CTAF heat exchangers have been the industry standard for decades, featuring copper tubes for corrosion resistance and aluminum fins for enhanced heat dissipation.

Advantages:

Durability: Copper resists corrosion better than aluminum in certain environments.

Proven Reliability: Long-standing use in HVAC and refrigeration systems.

Disadvantages:

Higher Cost: Copper is more expensive than aluminum.

Heavier: Increased weight impacts installation and transportation.

Lower Efficiency: Less surface area compared to MCHEs.

2. Aluminum Tube Aluminum Fin (ATAF) Heat Exchanger

ATAF exchangers use all-aluminum construction, reducing costs while maintaining decent thermal performance.

Advantages:

Cost-Effective: Aluminum is cheaper than copper.

Lightweight: Easier to handle and install.

Disadvantages:

Corrosion Sensitivity: Aluminum is prone to galvanic corrosion in certain conditions.

Lower Heat Transfer Efficiency: Compared to MCHEs.

Why Choose MCHE Over CTAF and ATAF?

While CTAF and ATAF exchangers remain viable for specific applications, MCHEs offer:

Better energy efficiency due to optimized microchannel flow.

Lower material and operational costs (reduced refrigerant use).

Environmental benefits (compliance with regulations like EPA and REACH).

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>